In the present day, continuous operation is a major necessity in base oil solvent extraction plants. With the increasing production capacities and longer operating cycles, the separation equipment must be very stable in performance even under feed conditions that are always the same. In this scenario, centrifugal extraction has emerged as a very practical alternative for refineries that want to keep their throughput continuous while at the same time enhancing process control and reliability.

Why Continuous Operation Matters in Base Oil Solvent Extraction

Base oil solvent extraction units are traditionally designed to operate for long periods without interruption. An interruption in the phase separation process has an immediate impact on the recovery of the solvent in the subsequent steps, the quality of the product, and the availability of the entire unit.

During the continuous extraction of base oil using solvents, the operators generally give priority to three things:

a. Stable capacity without constant adjustments

b. Quality of the product remains consistent even when feed conditions vary

c. Less operator intervention during long campaigns

These requirements, however, become increasingly difficult for traditional gravity-based separation methods to fulfill as the feed rates increase or even when solvent-to-oil ratios vary. Settling time is a limiting factor and can cause bottlenecks that forbid true continuous operation.

Centrifugal extraction allows resolution of these issues by providing fast and controlled phase separation, making the solvent extraction section a genuinely continuous process rather than a sequence of constrained steps.

How Centrifugal Extraction Supports Stable Continuous Extraction Processes

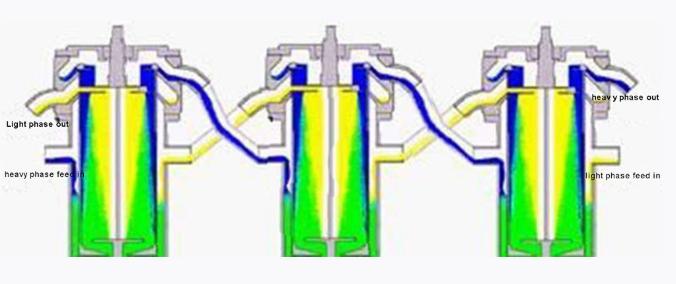

Continuous base oil solvent extraction operations must maintain separation efficiency even during minor process variations. Centrifugal extraction, which is a mechanical separation technique, provides a force that is not dependent on gravity; therefore, it is perfectly suited for non-stop operation.

Consistent Phase Separation Under Continuous Feed

Oil and solvent phases are fed into the extractor at the same time in continuous feed conditions. Phase separation is accelerated by centrifugal force, which keeps the separation performance constant even with increased flow rates.

Among the main advantages of continuous operation, we find:

- Very short and predictable residence time

- Lower sensitivity to variations in feed composition

- Emulsion accumulation is less likely to happen

These properties play a key role in maintaining the downstream climate at an even level, particularly in the solvent recovery and finishing stages.

Integration into Continuous Solvent Extraction Units

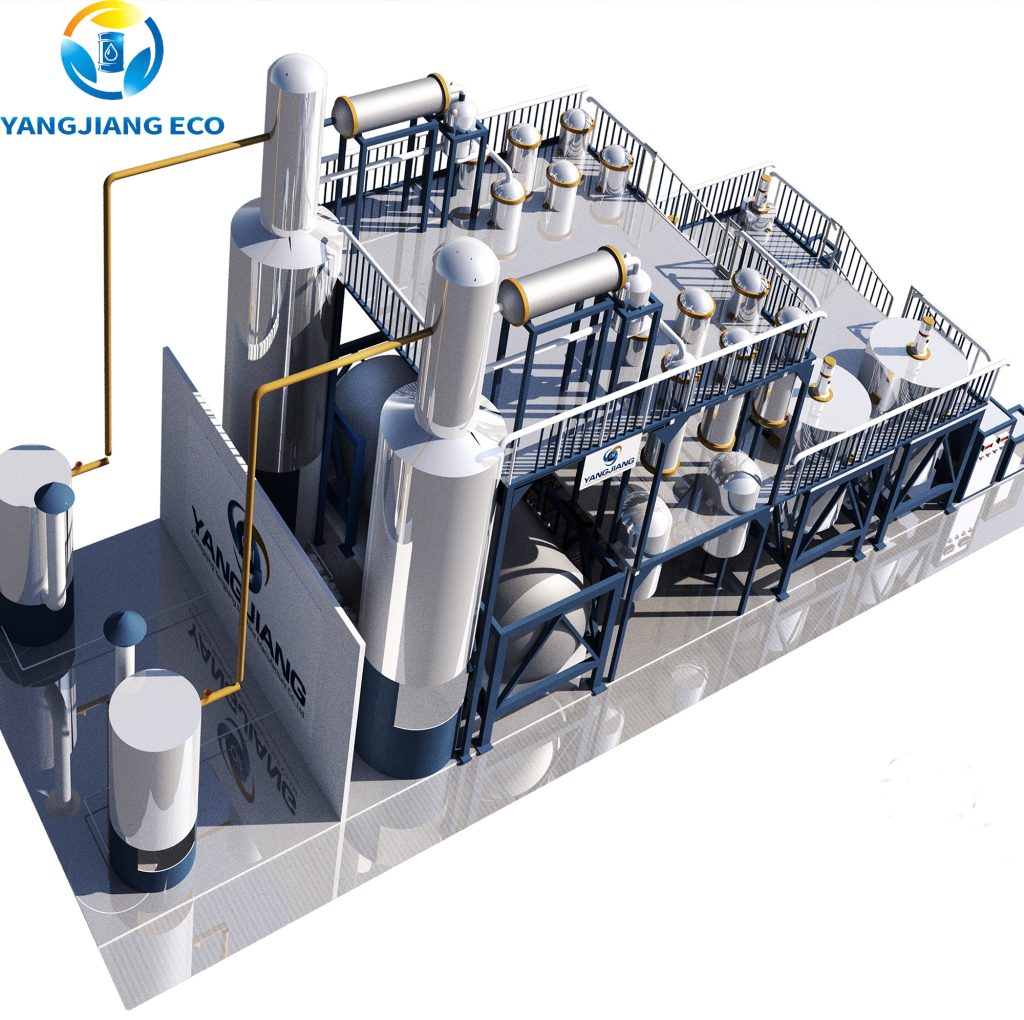

Centrifugal extraction equipments can be included directly in continuous solvent extraction units by the process without significant restructuring. The small size permits the positioning near the upstream extractors or contractors, thus reducing the time lag and pressure losses due to the transfer.

Looking at the operation side of things, centrifugal extractors act as a predictable and manageable separation stage that supports the overall process continuity instead of interrupting it.

Key Operational Advantages Compared with Conventional Separation Methods

In the process of assessing separation technologies suitable for solvent extraction, the operational performance usually takes precedence over the theoretical efficiency.

The following table illustrates the usual disparities in continuous base oil applications:

| Aspect | Centrifugal Extraction | Conventional Gravity Separation |

| Separation speed | Very fast | Slow |

| Footprint | Compact | Large |

| Sensitivity to load changes | Low | High |

| Emulsion handling | Strong | Limited |

| Suitability for automation | High | Moderate |

Reduced Process Bottlenecks in Continuous Operation

Separation capacity in continuous solvent extraction machines is one of the problems that co-exists with throughput, and it does not scale linearly. Increasing feed rates often leads to gravity separators becoming bottlenecks.

Centrifugal extraction equipment, in this case, would risk separation efficiency being dependent on residence time. Consequently, there was an opportunity for plants to:

- Increase throughput without expanding separation volume

- Maintain solvent-to-oil ratios that are stable

- Avoid poor phase disengagement leading to downstream disruptions

Improved Operational Stability and Control

In predictable equipment behavior, continuous operation enjoys a significant advantage. The centrifugal extraction systems provide:

- Stable separation performance through automated control

- More rapid response to process adjustments

- Less manual intervention is needed.

These features are even more important in large-scale base oil solvent extraction plants where unplanned downtime has a major economic impact.

Design and Selection Considerations

Choosing centrifugal extraction equipment for continuous base oil solvent extraction operations means placing a strong emphasis on long-term application conditions instead of short-term capacity goals.

Capacity Matching for Continuous Throughput

When it comes to continuous operation, the extractor must be designed according to the maximum expected flow rates and not the average ones. During selection, the variations in feed, solvent ratio changes, and future increase in capacity should be considered. An undersized unit can soon turn into a bottleneck, whereas the excessive oversizing just means more investments without any performance boost.

Mechanical Design and Reliability

The fact that the machines are in service continuously implies the highest requirement for mechanical integrity. The materials that are used for sealing and bearings must be very durable, and the sealing and bearing systems must be designed for long life. Reliable centrifugal extraction machine, on the other hand, minimizes the chances of unplanned outages and also reduces the number of times maintenance is performed.

Integration with Existing Process Units

Layout compatibility is essential in new installations as well as revamping projects. A compact design and flexible piping arrangements enable the centrifugal extraction process to be integrated into existing solvent extraction units with little structural modification, thus minimizing transition time to continuous operation.

Final Tips

Continuous base oil solvent extraction, water and solvent separation processes require modern separation technologies with the same high efficiency as those of today’s refineries. Centrifugal extraction presents clear operational advantages concerning stability, throughput, and integration into continuous processes.

When well chosen and designed, centrifugal extraction equipment turns into a significant factor for dependable continuous operation rather than merely an option for separation.

Our consultants are available to assist you in the case of specific project requirements or continuous operation difficulties by providing you with the most suitable technical consultation and centrifugal extraction equipment solutions for applying to base oil solvent extraction. Don’t hesitate to get in touch with us!

Recommended Products