For lubricant producers, choosing the right lube oil blending plant solution is not only a technical decision, but also a commercial and operational one. When projects involve cross-border communication, shipping, installation, and commissioning, the choice between a turnkey lube oil blending plant and a modular blending system can directly affect project risk, startup time, and long-term operating stability.

This article compares both solutions from the perspective of international buyers, focusing on execution, cost control, and real-world project experience.

Different Project Goals Lead to Different Blending Plant Solutions

The majority of lubricant blending projects can be classified into two main types:

- A new (greenfield) lube oil blending plant, where speed, coordination, and risk control are critical factors

- An expansion or modernization project, where flexibility and staged investment are of greater concern

Knowing the type of your project will help in making the choice sooner.

For new investors in the lubricant market, the main concern is to reduce the technical and execution risks. On the other hand, cost reduction, scalability, and integration with current systems may be the areas of focus for the existing producers.

This difference in the objectives of the projects is the very reason why turnkey and modular lube oil blending plant solutions are available—and why neither should be construed as a one-size-fits-all solution.

Turnkey Lube Oil Blending Plant: When a Complete Solution Makes More Sense

The turnkey lube oil blending plant is usually opted for in a situation where the client wants a single source to be responsible for the project, from engineering to commissioning.

Rather than having to coordinate several vendors, the owner of the plant only needs to work with one manufacturer, who provides them with an entire system that is ready to be operational.

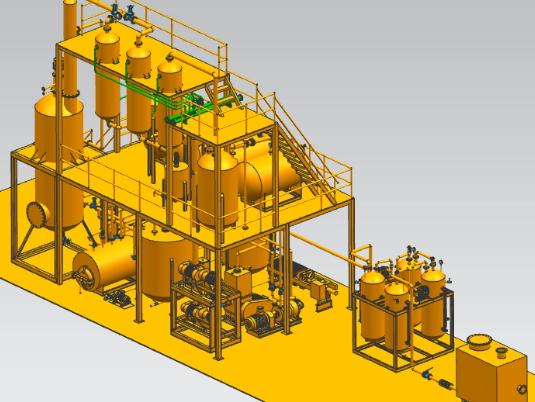

Typical scope of a turnkey lube oil blending plant

- Process design & plant layout

- Storage systems for base oil and additives

- Base Oil and Add

- Blending, Heating, and Transfer Systems

- Automation & PLC control

In the modern Installation, commissioning, and operator training

Why do many new lubricant manufacturers opt for a turnkey?

- The project execution time is significantly reduced, as engineering, fabrication, and installation are all handled under one plan, which minimizes delays.

- The coordination risk is also lower since there is one responsible party, making project management simpler.

- The performance is also predictable since the equipment, automation, and process logic are all designed as one integrated system.

For investors who do not have an in-house engineering team, a turnkey lubricant blending plant solution is often the quickest and most dependable route to commercial production.

Modular Lube Oil Blending System: Flexibility and Phased Investment

A modular lube oil blending plant is composed of process units that are either fully standardized or semi-standardized and can be installed one after the other.

This method is particularly appealing to manufacturers who wish to manage capital outlay or to increase their capacity gradually as the market demand rises.

How modular blending systems come into play for the expansion

- The very first installation may be limited to blending core functions

- Subsequent modules (storage, dosing, automation upgrades) may be introduced later

- It will be possible to expand both the capacity and the product range without the need to stop the whole plant.

When a modular system proves to be more sensible

- Old lubricant manufacturers are enhancing outdated plants

- Firms that have a solid local engineering and installation capacity

- Projects with uncertain short-term demand but clear long-term growth potential

Still, the modular systems need meticulous synchronization. The connection of modules, utilities, and control systems must be exquisitely planned; otherwise, later on, operational inefficiencies might emerge.

Key Comparison Factors You May Care About

To make a rational decision, lubricant producers should compare turnkey and modular solutions across several practical dimensions.

| Factor | Turnkey Lube Oil Blending Plant | Modular Blending System |

| Initial Investment | Higher, but predictable | Lower initial cost |

| Project Lead Time | Shorter | Longer, phased |

| Responsibility | Single supplier | Shared among parties |

| Automation Level | Usually fully integrated | Depends on configuration |

| Expansion Flexibility | Limited | High |

Cost Considerations

Provided that the price of a turnkey solution for the lube oil blending plant looks higher in the beginning, it usually comprises:

- Automation integration

- The risk of rework is lessened

- Quick start-up

Modular technology can bring down the initial cost, but it can also result in higher long-term costs if there are multiple upgrades and integrations to be done.

Operational Control and Automation

- In a typical turnkey project, it tusually deliver a unified PLC or SCADA system with centralized control.

- In modular plants, the uniformity of the automation is mainly determined by the system architecture and the suppliers’ cooperation.

However, for manufacturers who require very precise and reproducible blending, the design of the automation should not be treated as an afterthought but rather as a key criterion in the evaluation process.

How to Choose the Right Lube Oil Blending Plant for Your Business?

Selecting a proper lube oil blending plant is not primarily about its equipment but rather about whether it suits your production targets and long-term business strategy.

Consider these factors very carefully before arriving at a decision:

- Target production capacity: What will be your planned lubricant production volume over the next 3–5 years?

- Product range: Are you going to concentrate on engine oil, hydraulic oil, gear oil, or will it be multiple grades?

- Local engineering capabilities: Is there an in-house team to carry out system integration and installation, or will there be total reliance on the supplier?

- Project priorities: Is the speed of entering the market most important, or is the option of investing gradually with flexibility your main concern?

In answering these questions, you will get closer to determining if a turnkey or modular blending system corresponds to your requirements. The current market is full of manufacturers that offer bespoke blending solutions that not only promise the quickness of turnkey but also the gradualness of modular, thus giving the customer both the advantage of starting production right away and the option of expanding it later.

When in doubt about the best route to take for your project, you can have a consultant experienced in the lube oil blending plant manufacturing to help you with your question by saving you time, money, and preventing mistakes.

We invite you to reach out and discuss your production needs with us today; we will provide you with a personalized recommendation for your blending plant project!

Recommended Products