YJ-SNC Diesel Desulfurization Machine

Desulfurization, denitrification, and decolorization reduce the sulfur content in diesel down to 10ppm

- Oil recovery rate: nearly 100%

- Output oil sulfur: less than 10ppm

- Output oil color: 0.1-0.5

- Output oil standard: Euro V

- Handling capacity: from 10 kiloliters to 1000kiloliters per day

YJ-SNC Diesel Desulfurization Machine

Desulfurization, denitrification and decolorization, reduce the sulfur content in diesel down to 10ppm

The Importance of Diesel Desulfurization

The amount of sulfur in diesel affects the diesel’s impact on the surroundings and on people’s health. Combustion of diesel produces sulfur dioxide (SOx) and is a large contributor to a polluted atmosphere. The diesel industry needs to implement more diesel desulfurization to preemptively control air pollution. An effective way to achieve the desired air quality is to remove sulfur from diesel to lower SOx emissions. The air will become less polluted in and diesel desulfurization will improve the health of the public.

Due to the increasing environmental laws and upstream fuels purification technology, the demand for high-quality oil products has increased. The removal of sulfur, nitrogen, and other undesired elements of fuel became generalized. The hydrogenation process is effective in removing the unwanted elements, but it comes with challenges. The challenges are the high temperature and pressure systems, the expensive and deactivatable catalysts, high project investment and processing fee, and the systems needing to be hands-on and expensive. The increasing demand for safety and economic efficiency is not being met, considering the challenges at hand.

Developing unique, integrated methods of desulfurization and coupled with denitrification and decolorization, is greatly needed in the industry in this day and age. Primarily to lower the hydrogenation system.

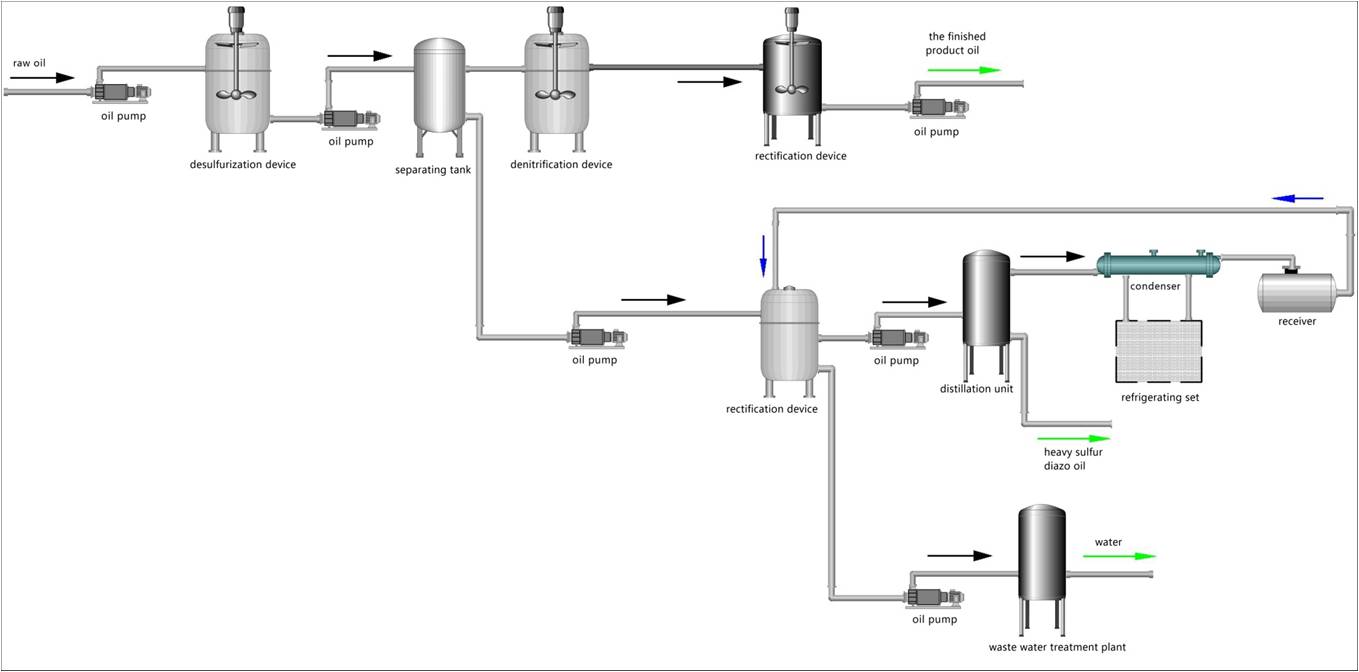

Technology Description of YJ-SNC Diesel Desulfurization Machine

YJ-SNC Diesel Desulfurization Machine technology uses liquid additives to dissolve solids in it to form liquid Lewis acid-based extractants. At the same time, the additives have unique planar structural characteristics, which can disperse the acidity of desulfurization and denitrification additives in the plane, thereby constructing a soft acid electronic structure. It can be seen that this technology can simultaneously achieve liquefaction of solid additives.

Application of YJ-SNC Diesel Desulfurization Machine

YJ-SNC Diesel Desulfurization Machine specializes in Deodorization, Desulphurization, Denitrification Refining Systems in One. Which is suitable for refine the following oil:

- Waste engine oil (distillation first)

- Diesel fuel from Crude oil

- Diesel oil from waste lube oil

- Black/red diesel

- Diesel fuel from Heavy fuel oil(HFO)

- Gas oil

Features and Advantage of YJ-SNC Diesel Desulfurization Machine

The focus of our diesel desulfurization technology is separate the raw oil into low-sulfur diesel oil and sulfur-rich oil that can be distilled or extracted again. The following are detailed features and advantages of our YJ-SNC diesel desulfurization machine

- Around 0.5% Chemical consumption, the chemical additives can be recovered and reused again and again, and the additive is highly active even at normal pressure and temperature.

- Compared with hydrogenation technology, YANGJIANG’s desulfurization technology has significant advantages in terms of effectiveness, economy, and safety.

- The liquid desulfurization and denitrification chemical can quickly dissolve the suspended solids in the oil to obtain a clear and transparent product oil, which can be recycled indefinitely.

- Zero pollution, no oily residue in the whole process.

- With a 100% recovery rate, the final oil output is essentially split into two parts: light-colored, low-sulfur and low-nitrogen product oil and dark-colored sulfur-rich and nitrogen-rich oil, with almost no oil loss.

- The sulfur can be reduced to less than 10ppm, which can meet the Euro V standard and can be directly used for cars.

Typical Cases Application of Diesel Desulfurization

Case 1: Refine High Sulfur Diesel from Crude Oil

This extraction technology can remove sulfur 99%, remove nitrogen more than 98% and the color will change to water-white. After blending, the diesel can reach Euro 6 standard.

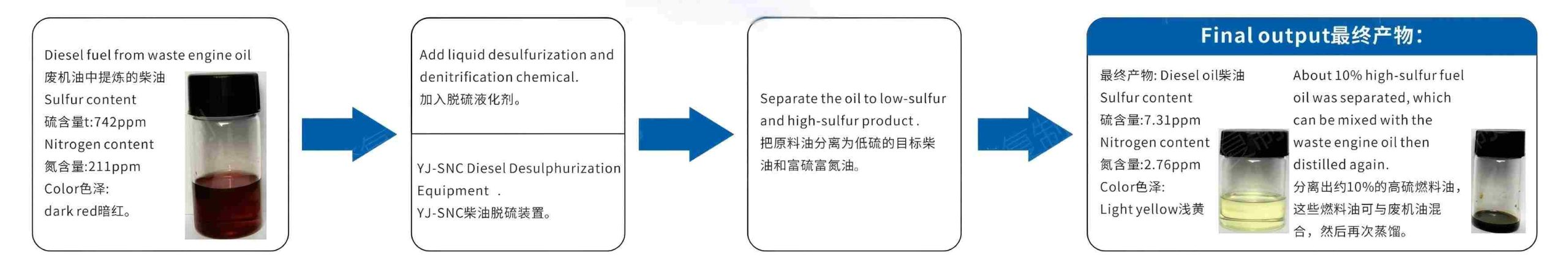

Case 2: Refine Distilled Diesel from Waste Engine Oil

About 10% high-sulfur fuel oil was separated, which can be mixed with the waste engine oil then distilled againRemove 99%sulfur and nitrogen, changed the oil color from dark red to light yellow, this diesel product apply to Euro 6 diesel standard.

Product Control Room