Base Oil Solvent Extraction Machine

The undesirable components in base oil and impurities can be removed through liquid-phase centrifugal extraction while taking advantage of the properties of organic solvents. This process, performed by a base oil solvent extraction machine, removes troublesome lubricating oil impurities, including polycyclic aromatic hydrocarbons, gum, and non-hydrocarbon compounds of oxygen, nitrogen, and sulphur, increases base oil viscosity index, lowers sulphur content and sulphur saturation of base oil to improve saturation.

YANGJIANG is a prominent supplier of base oil solvent extraction machines. There is a large, constant need for these machines in the oil processing industry, and we are recognised for research and innovations focused on quality and eco-friendly solutions. Our machines are used in the manufacture of API group II base oils of high quality. These base oils are a critical component of lubricating oils, lubricants, and industrial oils, and other oil-related products.

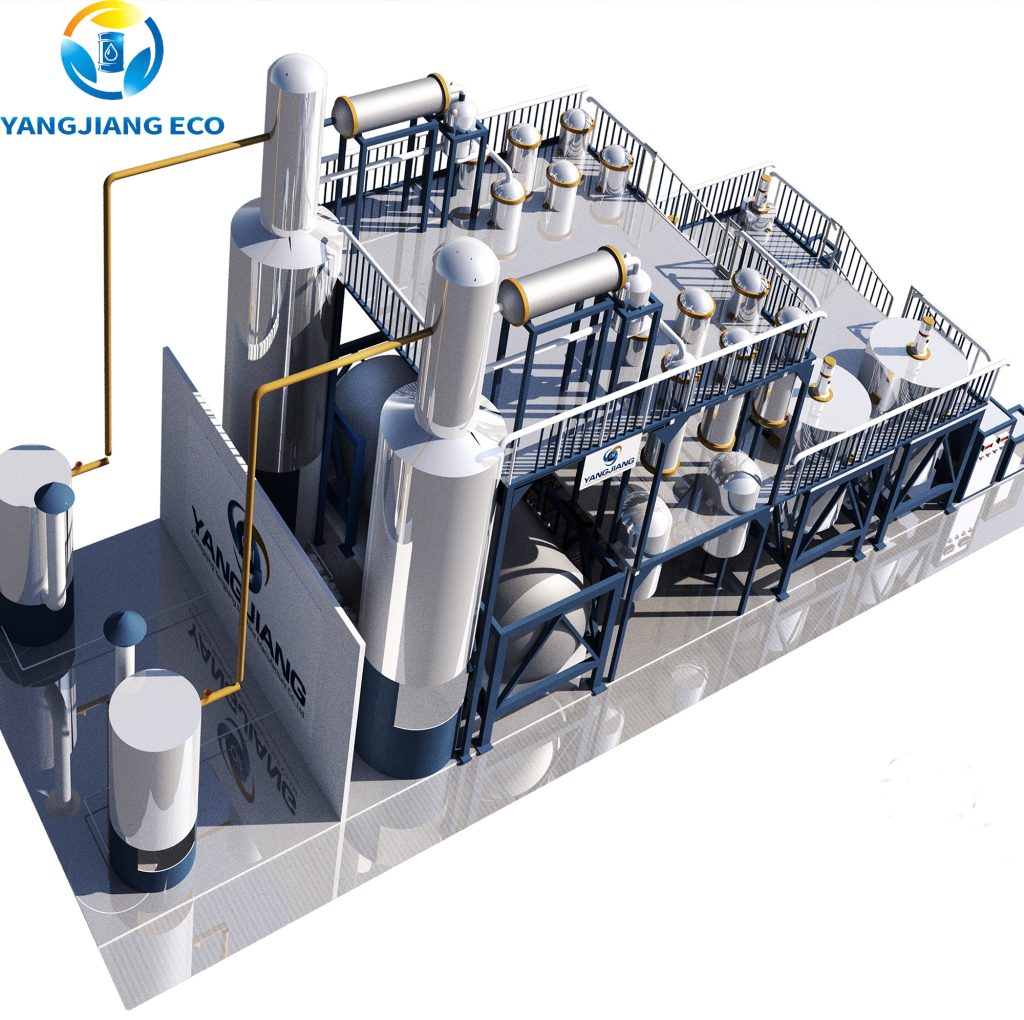

YJ-SR Waste Engine Oil to Group II Base Oil Refinery

API Group II Base Oil Re-refining Plant

YJ-SR Base Oil Solvent Extraction Machine

Application

Rich experience and solvent extraction technology

In the field of base oil regeneration, YANGJIANG provides global customers with comprehensive value solutions, from waste oil to high-end base oil, through an innovative solvent refining technology system. Our YJ-SR series integrates three core technologies: solvent desulfurization, solvent extraction, and hydrofining, which can convert various waste lubricating oils into high-quality base oils that meet API Class II standards.

YANGJIANG Company sincerely invites you to experience the innovative power of solvent refining technology and jointly create a new era in the base oil regeneration industry!

Expert Technical Team

We boasts a highly qualified technical team to deliver customers quality design services for waste oil recovery and oil refining projects. Comprised of masters and doctors with deep equipment design experience, our technical team offers engineering designs which meet international, national, and industry standards, such as preliminary designs, construction drawing designs, software control designs and preliminary process simulation. In addition, we can offer advanced services like container and pipeline process simulation, 3D designs, strength analyses, vibration analyses, safety analyses, software control as well as process simulation services to our customers.