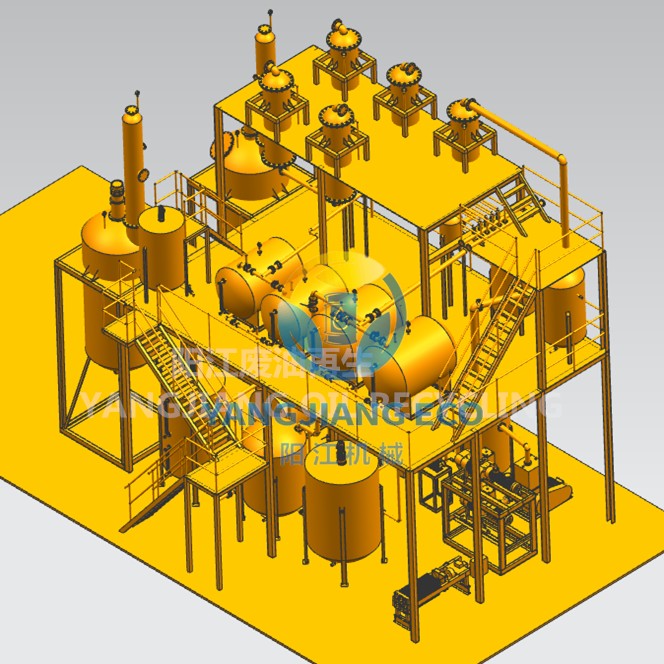

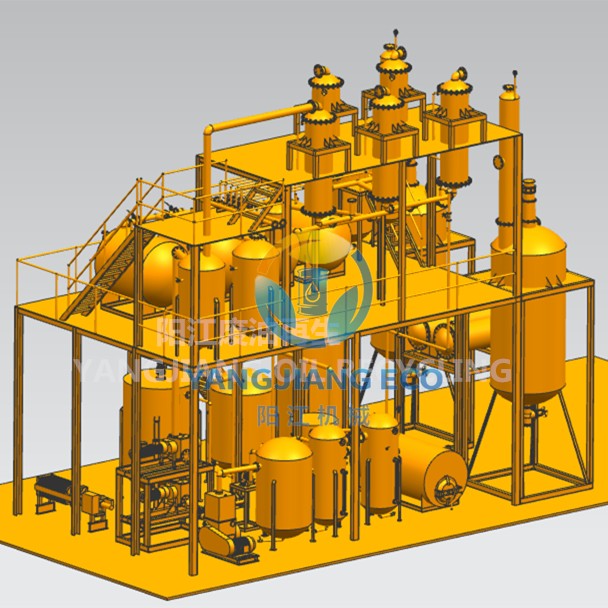

YJ-DSL Waste Oil to Diesel Distillation Plant

Convert waste oil into diesel fuel through high-temperature pyrolysis distillation.

- Regeneration rate: 93%-95%

- Temperature: ≤ 430℃

- Total power: 10-260 KW

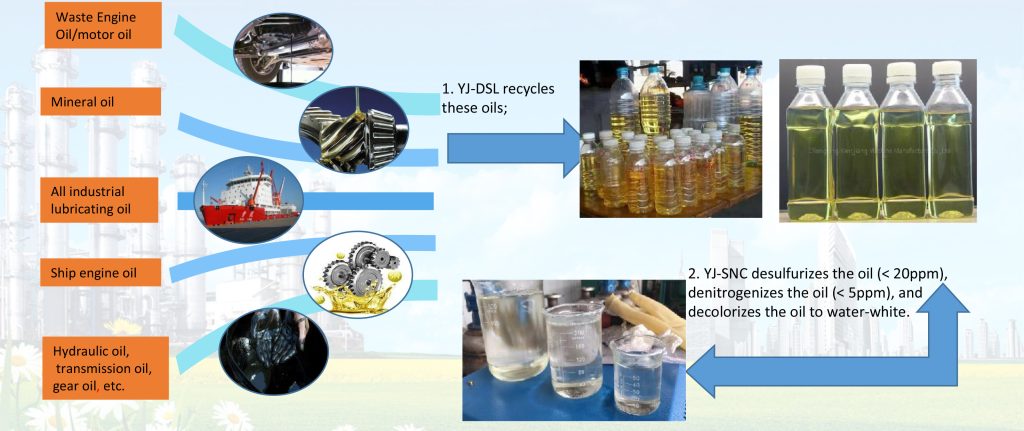

- Suitable oil: used gasoline and diesel motor oils, engine oils, mineral oils, synthetic oils, lubricants, transmission oils, hydraulic oils, and gear oils, etc.

Working Principle of YJ-DSL Waste Oil to Diesel Distillation Plant

The YJ-DSL waste oil to diesel distillation machine refines various types waste oils into clean diesel fuel. The equipment recycles high-quality diesel at a regeneration rate of 93%-95% with low cost and minimal environmental impact.

It separates fractions at different temperatures: 50-160°C for petrol and 160-410°C for diesel. After cracking and cooling, about 2-5% is gasoline and 85-90% diesel, meeting the standards of -15# diesel.

This diesel can be used as an industrial, civil, or power-driven fuel. Since motor oil and diesel share the same petroleum origin but have different molecular weights, the conversion of motor oil to diesel becomes quite feasible.

Technical Parameter of YJ-DSL Waste Oil to Diesel Distillation Plant

| Machine Parameter | ||||||||||

| Handling capacity | T/D | 0.5 | 2 | 4 | 5 | 10 | 20 | 30 | 50 | 100 |

| Recovery rate | % | <=93 | ||||||||

| Teperature | ≤ 430 | |||||||||

| Working Noise | dB (A) | 45 | 60 | 65 | 65 | 65 | 70 | 70 | 75 | 75 |

| Total power | KW | 10 | 15 | 20 | 22 | 55 | 90 | 130 | 170 | 260 |

| DimensionMM | L | 5000 | 8000 | 1100 | 12000 | 14000 | 25000 | 30000 | 60000 | 100000 |

| W | 3500 | 4000 | 4500 | 5000 | 8000 | 8000 | 10000 | 16000 | 22000 | |

| H | 6000 | 7000 | 7000 | 7000 | 7000 | 8000 | 8000 | 8000 | 8000 | |

Raw Material Range Used in YJ-DSL Waste Oil to Diesel Distillation Machine

This machine can treat used gasoline and diesel motor oils, engine oils, mineral oils, synthetic oils, lubricants, transmission oils, hydraulic oils, and gear oils, etc. After recycling, it can get diesel with a recovery rate is more than 85%. If you want to get high-quality diesel oil, the best solution is to choose both machines: DSL and SNC models.

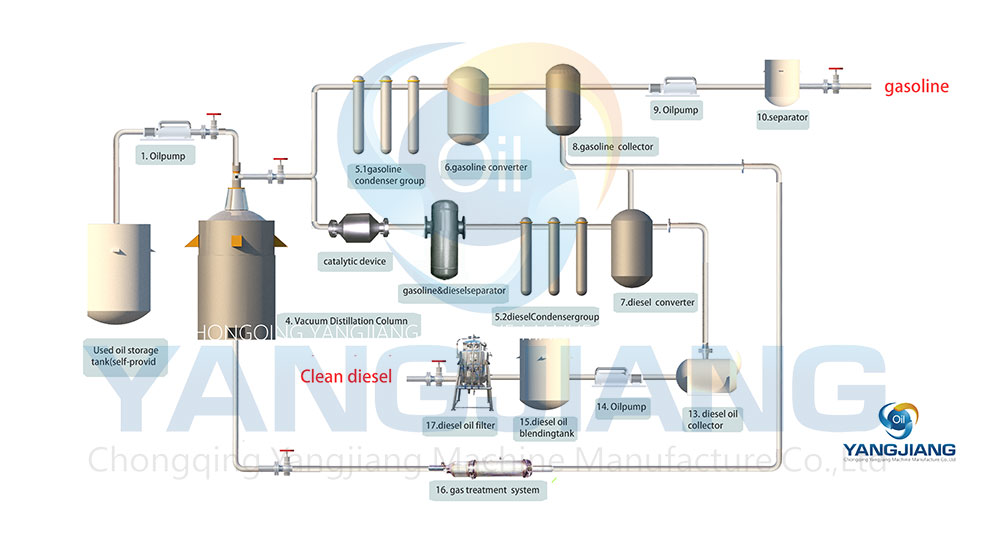

Working Process of YJ-DSL Waste Oil to Diesel Distillation Plant

The working process for the YJ-DSL waste oil to diesel distillation plant:

- Pump the waste oil into the distillation kettle, and the heating system will start the stirring device.

- Gasoline components and water in the used oil can be distilled out when the temperature reaches 50 ℃-100℃.

- When the temperature reaches 160 ℃-260℃, after efficient catalytic cracking, the light and heavy components will convert to diesel from vapor.

- Finally, we filter all the collected diesel oil, and then we can get high-quality finished diesel oil.

Cracking Process of a YJ-DSL Waste Oil to Diesel Distillation Machine

Cracking is one of the principal ways in which used oil is converted into useful fuels such as motor gasoline, diesel fuel, and home heating oil. It is a petroleum refining process in which heavy-molecular-weight hydrocarbons are broken up into light hydrocarbon molecules by the application of heat and pressure, with or without the use of catalysts, to derive a variety of fuel products.

Cracking breaks carbon-carbon bonds to turn heavier hydrocarbons into lighter ones. This can occur thermally (as occurs during the petroleum formation process beneath the earth) or through the action of a catalyst.

The method for scrap engine oil to standard clean diesel oil distillation refinery machine is to crack it into fuel. The feature for the cracking process is very safe cause the temperature setting is rigorous and the machines are stabilized.

Our engineers commit to designing the most reasonable and highly efficient distillation system to realize the profit maximization of both parties.

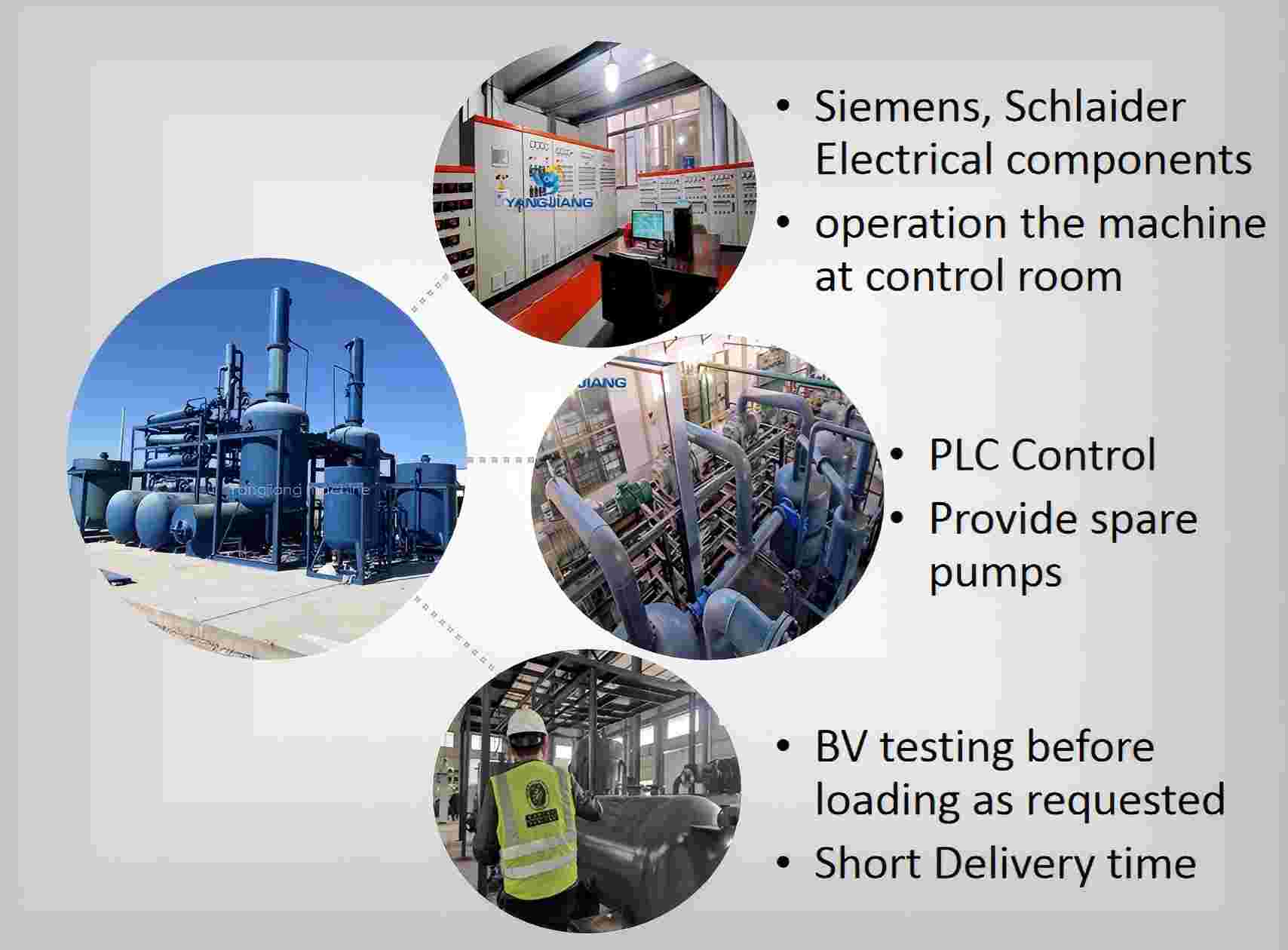

Features of a YJ-DSL Waste Oil to Diesel Distillation Plant

Our YJ-DSL waste oil to diesel distillation machine offers the following advantages:

- High recovery rate: The highest recovery rate can reach 93-95%. Gasoline 2-5%, diesel fuel 85-90%.

- Easy operation: The YJ-DSL series machine is easy to operate, with low running costs; it needs only 1-2 workers to operate.

- Rich raw material: YANGJIANG’s YJ-DSL series can recycle all kinds of used black diesel, used engine oil, used machine oil, used mineral oil, and almost all industrial oils to diesel fuel. The cracked oil is able to be used as industrial or civil-use fuel, even power-driven fuel.

- Efficient catalyst: It is normally safe and available. It can help the waste oil undergo further catalytic cracking to ensure a higher recovery rate and good quality of oil. The output oil can be used in ships, generators, as fuel for boilers, construction machines, Agriculture machines, etc.

Recycled Oil Report from YJ-DSL Waste Oil to Diesel Distillation Plant

| Item | Test standard | result | Standard value |

| Density(15℃) | ASTM D1298 | 0.84kg/l | |

| kinematic viscosity(40℃) | ASTM D445 | 3.36cst | 1.6-5.8cst |

| Flash point(closed cup) | ASTM D93 | 60℃ | ≥55℃ |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0℃ |

| Distillation temperature | |||

| 10% point | ASTM D86 | 204 ℃ | |

| 50%point | 289 ℃ | ≤300℃ | |

| 90% point | 344 ℃ | ≤355℃ | |

| 95% point | 359 ℃ | ≤365℃ | |

| Cetane index | ASTM D976 | 54.42 | ≥45 |

| Water content | ASTM D95 | Trace %vol | ≤Trace%vol |

| Sulfur content | ASTM D1226 | 0.151 %wt | ≤0.2%wt |

In addition to the YJ-DSL Waste Oil to Diesel Plant, we also provide other used oil re-refining plants, such as Diesel Desulfurization Machine, Base Oil Solvent Extraction Machine, Base Oil Blending Plant, and Transformer Oil Regeneration Machine.

YANGJIANG Machine Manufacture Co., Ltd has unique technology and rich experience in the waste oil recycling industry. The company constantly seeks development, extensively absorbs the world’s advanced oil purification technology, and is committed to research and development in the field of oil treatment.

Welcome to contact us for more details! (+86 133 9980 7550 WhatsApp / WeChat 24-H service).