YJ-DSL Lube Oil Refinery Plant

Convert used oil into diesel fuel through high-temperature pyrolysis distillation

- Recovery Rate: 85%-90%

- Recycled diesel oil flash point: 60℃

- Recycled diesel oil sulfur: lower than 0.15%wt

- Suitable oil: waste engine oil, motor oil, black diesel, industrial lube oil, transmission oil, or mixed oil

The Importance of Recycling Used Oil into Diesel fuel?

- Fulfilling Oil Shortage and Assuring Energy Security: The recycling of waste engine oil into diesel helps relieve the oil shortage. With the faster growth of the economy, oil demand continues to rise. By converting waste engine oil into valuable diesel, wasteful resources are conserved, dependence on foreign oil is reduced, and national energy security is assured.

- Reduction of Environmental Pollution: Waste engine oil creates extremely severe environmental pollution if disposed of in the form of direct discharge or incineration. Recycling and regeneration of waste engine oil to diesel not only minimizes its negative environmental impact but also transforms waste into useful fuel.

- Developing Substantial Economic Benefits: Waste engine oil recovery to diesel has a strong market demand. It not only produces high-value products in this process, but also develops substantial economic benefits.

Specification of YJ-DSL Lube Oil Refinery Plant

| Function | Waste engine oil, motor oil, black diesel, industrial lube oil, transmission oil, or the mixtural oil |

| What kinds of oil can be recycle | electromagnetic heating system, burner, hot gas, or tubular heating system |

| Recovery Rate | 85%-90% |

| Heating method | What kinds of oil can be recycled |

| Warranty | 12 months |

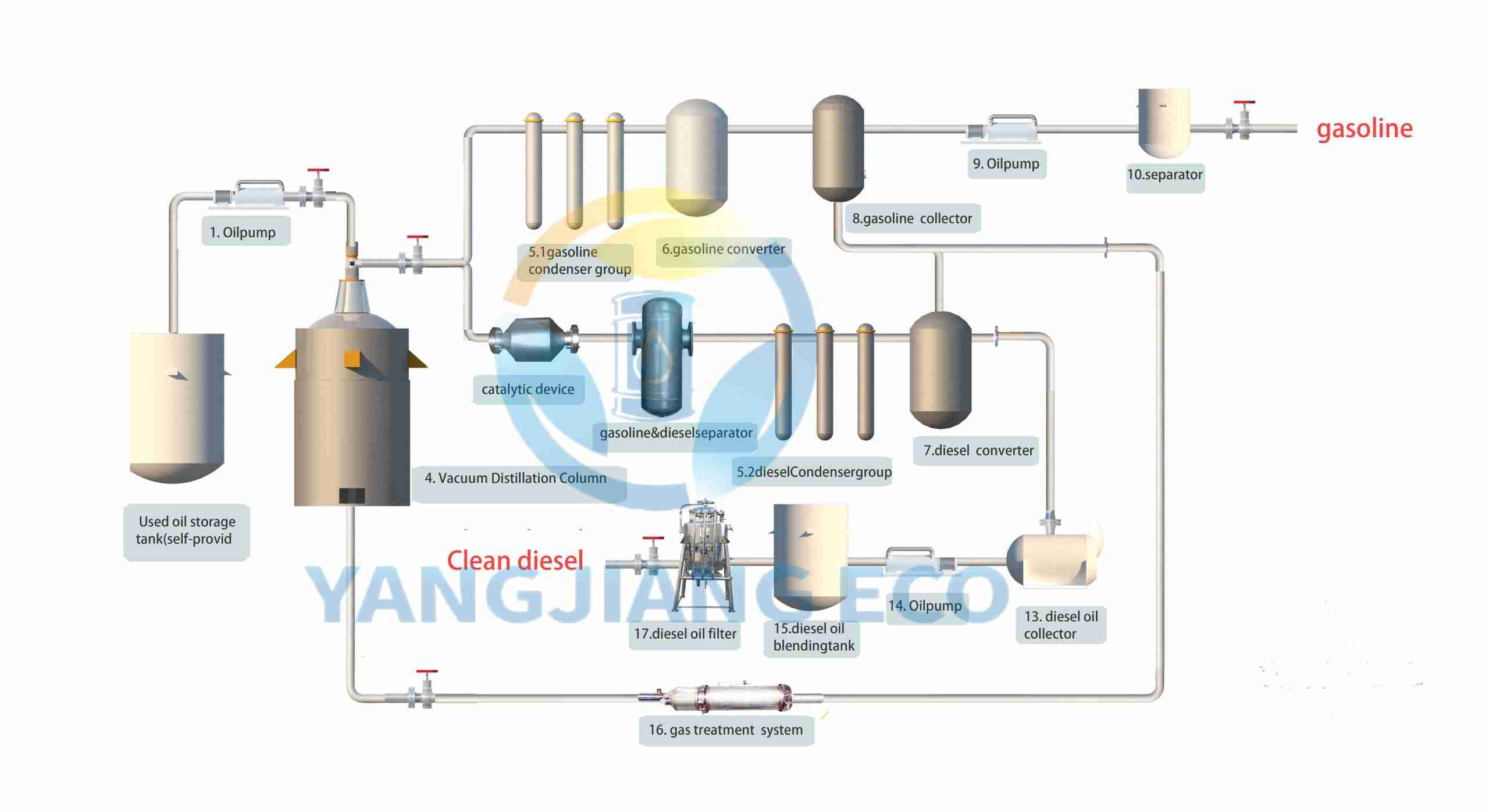

Working Process of YJ-DSL Lube Oil Refinery Plant

Oil contains many hydrocarbons of different sizes. Each type of hydrocarbon has unique properties, and therefore, oil is useful for the production of a range of products.

The cracking process is a key process in petroleum refining in which the heavy hydrocarbons are broken into smaller molecules. It is accomplished by exposing it to heat and pressure, at times with the addition of catalysts.

By cracking, the carbon–carbon bonds are broken, and heavier hydrocarbons are broken down to lighter hydrocarbons. It is one of the major methods in which used oil is processed into useful fuels such as motor gasoline, diesel oil, and heating oil.

Features of a YJ-DSL Lube Oil Refinery Plant

- High recovery rate: The highest recovery rate can reach 87-90%, including Gasoline 2-5%, diesel fuel 83-85%.

- Easy operation: The YJ-DSL series machine is easy to operate, low running cost, it needs only 2-3 workers to operate.

- Rich raw material: YANGJIANG’s YJ-DSL series can recycle all kinds of used black diesel, used engine oil, used machine oil, used mineral oil, and almost all industrial oil to diesel fuel. The cracked oil is able to be used as industrial or civil-use fuel, even power-driven fuel.

- Efficient catalyst: It is normally safe and available. It can help the waste oil undergo further catalytic cracking to ensure a higher recovery rate and good quality of oil. The output oil can be used in ships, generators, as fuel for boilers, construction machines, agriculture machines, etc., directly.

What Kinds of Catalysts We Use?

YANGJIANG has been committed to researching and developing new technologies, continuously breaking through the oil recycling technologies. We have discovered this liquid catalyst through continuous experiments. The catalyst is safe to use, it won’t cause machine coke, helps to get better diesel color and diesel smell, lower sulfur content, and pour point.

Many people use solid catalyst after distillation, we use it before, but the problem is that the catalyst is easy to block or coke when hot oil vapor passes through the solid catalyst. It is normally safe and available. It can help the waste oil undergo further catalytic cracking to ensure a higher recovery rate and good quality of oil.

Recycled Oil Report from YJ-DSL Lube Oil Refinery Plant

| Item | Test standard | result | Standard value |

| Density(15℃) | ASTM D1298 | 0.84kg/l | |

| kinematic viscosity(40℃) | ASTM D445 | 3.36cst | 1.6-5.8cst |

| Flash point(closed cup) | ASTM D93 | 60℃ | ≥55℃ |

| Pour point | ASTM D97 | -19 ℃ | ≤ 0℃ |

| Distillation temperature | |||

| 10% point | ASTM D86 | 204 ℃ | |

| 50%point | 289 ℃ | ≤300℃ | |

| 90% point | 344 ℃ | ≤355℃ | |

| 95% point | 359 ℃ | ≤365℃ | |

| Cetane index | ASTM D976 | 54.42 | ≥45 |

| Water content | ASTM D95 | Trace %vol | ≤Trace%vol |

| Sulfur content | ASTM D1226 | 0.151 %wt | ≤0.2%wt |

What We Offer?

- YANGJIANG will provide the PID and the layout before manufacturing the machine.

- Using high-quality raw materials from famous suppliers, Schneider or Siemens, or equivalent brand electrical components can be chosen.

- PLC automatically controls explosion-proof motors.

- Leakage inspection and pressure test are strictly conducted after finishing making the machine.

- Engineers are available to go to the site to help install and commission the machine.

YANGJIANG has been committed to solving various waste oil purification problems. In addition to the above waste oil recycling plants, we also provide other used oil re-refining plants, such as Waste Oil to Base Oil Vacuum Distillation Plants, Diesel Desulfurization Machines, Base Oil Solvent Extraction Machine, Base Oil Blending Plant, and Transformer Oil Regeneration Machine.