Waste Engine Oil Recycling Machine

Machinery and equipment require lubricating oil for functioning, which also becomes contaminated with use. Nevertheless, very few of the lubricating oil hydrocarbons degrade over time.

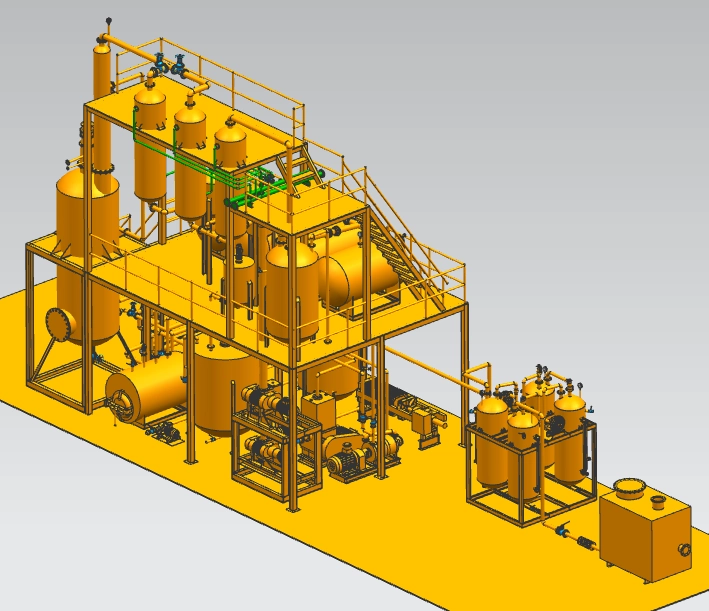

Waste engine oil recycling plants can employ vacuum distillation to recycle used lubricating oil to yield high-quality base oil along with some petrol and diesel. This approach presents considerable value on a large-scale industrial scale, given its cost-effective, high-quality, and eco-friendly production.

YANGJIANG offers oil recycling plants, waste oil refining machines, solvent extraction plants, and oil testers. We build our reputation on the quality of our affordable and reliable products. We are also known for the user-friendliness of our waste engine oil recycling systems. Please feel free to get in touch with us for additional details!

YJ-TY Lube Oil Recycling Plant for Used Oil

YJ-TY Waste Engine Oil Refining Plant

YJ-TY Base Oil Distillation Machine

APPLICATION

YANGJIANG waste engine oil recycling machines can be used in:

Advanced technologies for waste oil refining

YANGJIANG’s innovatively developed YJ-TY series waste engine oil recycling system integrates the “molecular distillation + catalytic refining + deep hydrogenation” trinity process to create a complete industrial chain from waste oil recovery to high-value utilization. The original “thin film evaporation-white clay refining-hydrogenation quality improvement” process chain can not only process conventional oil products such as 4S shop waste oil and industrial waste lubricating oil, but also deeply process ship waste oil and special waste oil containing metal impurities. The base oil color is stable below 1.0, meeting the production needs of high-end oil products such as transformer oil and white oil.

Choose YANGJIANG, you will get integrated engineering services including process design, equipment installation, and personnel training, and quickly achieve a win-win situation of environmental protection and economic benefits!

Invention Patents

YANGJIANG have worked closely with Chinese universities to advance oil recycling technologies, earning invention patents for used oil regeneration systems, diesel oil desulfurization systems, and waste oil extraction and denitrification processes. Newly developed residual oil cracking technology combined with an advanced exhaust gas catalytic purification system creates a pollution-free and emission-free operation environment.

For more details about YANGJIANG, you can view the About Us page.