Diesel Desulfurization Machine

With the increasing awareness of environmental protection, countries around the world have implemented new regulations that strictly limit the sulfur content in fuel oil. Currently, catalytic hydrogenation or hydrocracking is primarily used for reducing sulfur; however, this technology has high equipment requirements, including high temperatures and pressures, as well as high equipment value and significant investment.

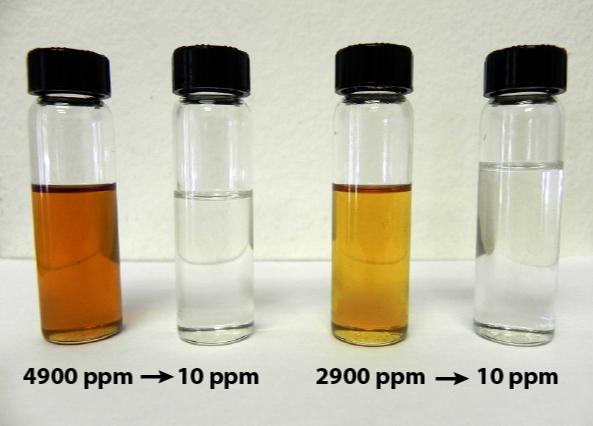

To solve these problems, YANGJIANG R&D team cooperates with universities to research this new diesel desulfurization and denitrification technology, producing the YJ-SNC series Diesel and Black Diesel Desulfurization Plant. They can reduce the sulfur content of diesel to around 10 ppm. The output diesel fuel can be directly used for vehicles.

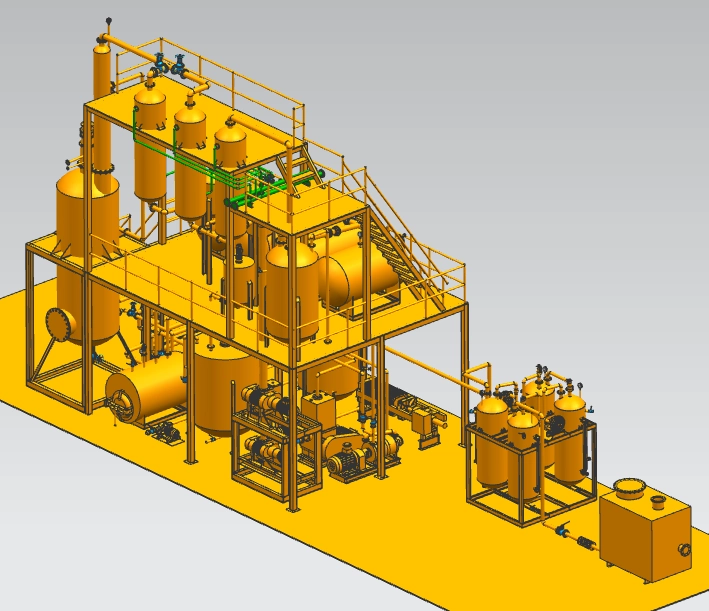

YJ-SNC Diesel Desulfurization Machine

YJ-SNC Black Diesel Desulfurization Plant

APPLICATIONS

Our YJ-SNC series diesel desulfurization machine specializes in deodorization, desulphurization, denitrification, and refining system in one. Which is suitable for refining the following oil:

- Waste engine oil (distillation first)

- Diesel fuel from Crude oil

- Diesel oil from waste lube oil

- Black/red diesel

- Diesel fuel from Heavy fuel oil(HFO)

- Gas oil

LASTEST PROJECT

Advanced technologies for diesel desulfurization

With over 20 years of experience in used oil recycling, YANGJIANG has built a strong reputation in the industry.

For diesel desulfurization, we adopt extraction desulfurization technology based on carbocation base, which has the advantages of normal temperature and pressure, high safety, controllable raw material costs, and high efficiency. Through this new desulfurization technology, the liquid chemical is used to dissolve the solid positive substances in this technology, so as to realize its liquefaction.

Our continuous improvements in production techniques, scheduling, and quality control ensure we deliver reliable, top-quality products, meeting diverse customer needs and reinforcing our technical strength in the market.

Consulting Services

YANGJING’s technical team boasts longstanding expertise and a professional technical team that specializes in waste oil recovery and oil refining projects, offering various consulting services for clients such as project investment research, concept design, feasibility study, overall planning and design, and post-production evaluation services. We use engineering theory and practice, economic management practices, as well as laws and regulations, as the basis of providing consulting services that help with decision making for these waste oil recovery and refining projects.

FAQ