In the oil processing industry, efficient extraction is key to maximizing yield and profitability. Centrifugal extractors have revolutionized solvent-based oil extraction by enabling faster, more efficient separation of oil from raw materials. These high-speed machines use centrifugal force to enhance solvent recovery, reduce waste, and improve processing capacity.

Basics of Oil Solvent Extraction

Oil solvent extraction is an extremely efficient industrial method used to extract oil from seeds, nuts, and other oil-bearing materials such as soybeans. Unlike mechanical pressing, which leaves residual oil behind in its feedstock, solvent extraction ensures near-complete oil recovery – perfect for low oil content crops such as soybeans, rice bran, and cottonseeds.

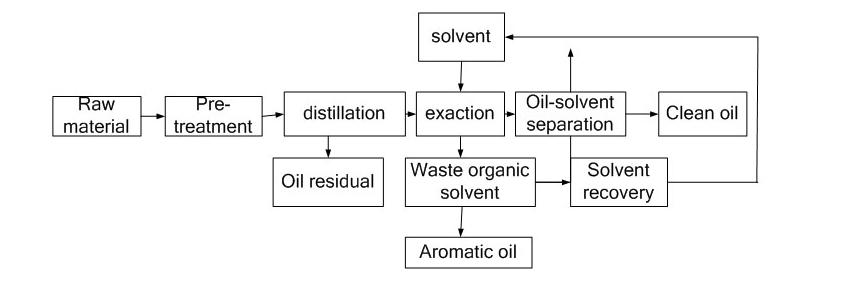

The process involves three key stages:

- Preparation – Raw materials are cleaned, dehulled, and flaked to increase surface area for better solvent penetration.

- Extraction – The flakes are mixed with a solvent (typically food-grade hexane), which dissolves the oil, forming a liquid mixture called miscella.

- Separation & Recovery – The miscella is separated from the solid residue (meal), and the solvent is evaporated and recycled, leaving behind pure crude oil.

Solvent extraction is preferred due to its high yield (up to 99% oil recovery) and energy-saving abilities compared to traditional pressing methods, while producing defatted meal, which can be used in animal feed production.

However, the process requires strict safety measures due to the flammability of solvents. Modern plants use closed-loop systems to minimize solvent loss and environmental impact.

By integrating advanced equipment like centrifugal extractors, the process becomes even more efficient, ensuring faster separation and higher-quality oil output.

What is a Centrifugal Extractor?

A centrifugal extractor (also known as a centrifugal contactor or centrifugal separator) is a high-speed rotating device designed to enhance liquid–liquid extraction. Unlike conventional static mixers or columns, it uses centrifugal force to accelerate the mass transfer and separation of two immiscible liquids—in oil processing, typically oil miscella and aqueous wash streams or solvent-rich and solvent-lean phases.

Key components include the following:

- Rotor/Stator Assembly: Used for fine dispersion of one liquid into another liquid.

- Centrifugal Separation Chamber: Producing high g-forces (often several thousand times gravity) to quickly separate phases by density.

- Feed and Discharge Ports: Provide precise metering of inlet flows and collection of individual streams.

Centrifugal extractors are compact, continuous, and energy-efficient machines, which make them attractive choices for modern oil solvent extraction plants looking to increase throughput and solvent recovery.

How Centrifugal Extractors Work in Oil Solvent Extraction

Centrifugal extractors streamline oil solvent extraction by leveraging high-speed rotational force to achieve rapid and efficient separation. Unlike traditional methods that rely on gravity or filtration, these machines accelerate the extraction process through mechanical action. Here’s a step-by-step breakdown of their operation:

- Feeding the Slurry: The oilseed material, pre-treated (flaked or crushed), is mixed with a solvent (typically hexane) to form a slurry. This mixture is pumped into the centrifugal extractor’s rotating drum at a controlled rate.

- Centrifugal Separation: Within an extractor, high-speed rotors rotate at speeds between 3,000-6,000 RPM to generate intense centrifugal force that moves slurry inward toward the drum wall while lighter oil-solvent miscella remains closer to the center.

- Dual-Phase Discharge: Solids removed by de-oiling are pushed along the drum’s periphery and discharged using an adjustable discharge mechanism, often assisted by an internal screw conveyor for continuous removal. Miscella (oil + solvent mixture) flows inward before being extracted through a central outlet to guarantee minimal oil residue remaining in meal products.

- Countercurrent Washing (Optional): Some advanced centrifugal extractors offer multi-stage countercurrent washing systems. Fresh solvent is introduced at various points during extraction to maximize oil recovery while increasingly cleaner miscella is extracted, increasing efficiency.

- Closed-Loop Solvent Handling: Miscella is sent to a distillation unit where its solvent can be evaporated off, leaving pure oil as output. Discharged solids (meal) then undergo desolventizing processes to remove residual solvent before further use as animal feed (for instance).

Centrifugal extraction’s unique ability to separate phases according to density differences, combined with precise control over rotor speed, feed rate, and discharge settings, ensures high throughput rates with reduced solvent retention levels for consistent oil yield and minimal percolation times – an invaluable advantage in large-scale, time-sensitive operations.

Advantages of Centrifugal Extractors in Oil Processing

Centrifugal extractors offer significant benefits in oil solvent extraction, making them a preferred choice for modern processing plants. Here are the key advantages:

- Centrifugal force ensures near-complete oil separation with up to 99% recovery even from low oil-content materials such as soybeans or rice bran.

- High-Speed and Continuous Operation – In contrast with batch processes, continuous extraction systems operate nonstop to boost productivity while decreasing downtime for large industrial applications.

- Reducing Solvent Consumption – Our precise separation technology reduces solvent retention in meal, cutting costs and increasing recovery rates of this vital commodity.

- Compact & Space-Saving Design – Vertical extraction systems require less floor space, making them perfect for facilities with limited room available for expansion.

- Reduce Energy & Labor Costs – Automated operation reduces manual intervention while efficient mechanics utilize less power compared to older extraction methods.

By enhancing yield, speed, and cost-efficiency, centrifugal extractors are revolutionizing oil processing—delivering higher profitability with sustainable operations.

Applications of Centrifugal Extractors in the Oil Industry

Centrifugal extractors have become increasingly important in various stages of oil production, particularly where precision, efficiency, and solvent recovery are critical. Here are the four most significant applications of centrifugal extractors in the oil industry:

1. Biofuel and Algae Oil Production

With the growing demand for sustainable energy, centrifugal extractors play a vital role in extracting oil from algae and microbial biomass. These feedstocks often have high water content and require delicate separation of oil, water, and residual solids. Centrifugal extractors offer a low-shear environment and fast phase separation, which helps preserve oil quality while increasing extraction efficiency—an essential requirement in biodiesel and renewable fuel production.

2. Vegetable Oil Extraction from Oilseeds

Centrifugal extractors are widely utilized for solvent extraction of vegetable oils from raw materials like soybeans, rapeseed (canola), sunflower, and cottonseed seeds. After being flaked up and immersed into solvent, oil dissolves into it forming miscella that needs to be separated from solid meal and any leftover solvent or water by centrifugation extraction equipment – something it does extremely efficiently due to high throughput with precise phase separation for maximum recovery rates while simultaneously decreasing solvent loss making it ideal for large-scale edible oil production facilities.

3. Solvent Recovery and Washing

In oil processing, effective solvent recovery is key to both environmental compliance and cost-efficiency. Centrifugal extractors are often utilized for this task to clean off impurities from extracted meal with water or lean solvents in order to increase solvent recovery rates and maximize solvent recovery. Their high centrifugal force facilitates quick separation between oil/solvent mixture and waste water collection while simultaneously decreasing wastewater volume, while improving recovered solvent quality – an invaluable step that saves both money and energy in distillation units downstream!

4. Effluent and Waste Stream Treatment

Centrifugal extractors are also used to treat process effluents that contain residual oil or solvent. By separating recoverable oil from wastewater streams, these machines minimize product losses and reduce environmental discharge. This not only supports sustainability efforts but also contributes to the overall process economy by reclaiming valuable resources from waste.

Final Thought

Centrifugal extractors have revolutionized oil solvent extraction by providing efficient mixing and rapid phase separation in one compact unit. Their superior throughput, energy savings, and flexibility make them indispensable in modern edible oil refineries, specialty chemical plants, and biofuel operations alike. As global demand increases for sustainable high-purity oils such as edible olive oil or biodiesel production, centrifugal extraction technology will continue to play an essential part in driving both economic and environmental performance within the oil industry.

Recommended Products