Today, sustainability and resource efficiency are two major strategic priorities being pursued across manufacturing, transportation, and energy sectors. In industrial operations, lubricants, hydraulic oils, and specialty fluids play a crucial role in maintaining machinery performance. For such fluids, once their useful life span expires or contamination sets in, they are unable to function effectively and generally are treated as waste.

Instead of disposal, industrial used oil recycling presents a cleaner, more cost-effective, and environmentally responsible alternative. Through advanced re-refining processes, companies are able to restore used oil back into valuable base oil, lowering both operational costs and environmental risks.

The article describes the basics of industrial oil recycling, outlines the main processes, and introduces the top technologies that drive innovation in the industry.

What Is Industrial Oil Recycling and Its Importance

Industrial oil recycling is the system of collection, cleaning, and re-refining of used industrial oils, such as lubricants, hydraulic fluids, and cutting oils, that can be safely and effectively reused. It differs from mere disposal by emphasizing the recovery of valuable base oils while minimizing environmental impacts.

Modern manufacturing and heavy industries cannot avoid the use of lubricants or hydraulic oils. Without proper recycling, these become hazardous wastes that pollute soil and water sources.

The importance of industrial oil recycling has dual economic and environmental benefits:

- Cost reduction: Re-refined oil will have significantly reduced raw material costs when compared to procuring new base oil.

- Sustainability: The process of recycling significantly contributes to achieving circular economy goals and reduces carbon emissions.

- Regulatory compliance: Most regions now have legislations that require proper treatment of used oils to avoid environmental pollution.

Industrial oil recycling is no longer an option for businesses looking to meet sustainability targets and cut operating costs; it’s a strategic necessity.

Main Industrial Used Oil Recycling Process

The reclamation of waste oil into a reusable resource greatly depends on precision and a multi-step process of purification. In essence, the effective process of recycling used oil in industries should be systematic, where impurities are removed step by step to recover the useful base oil.

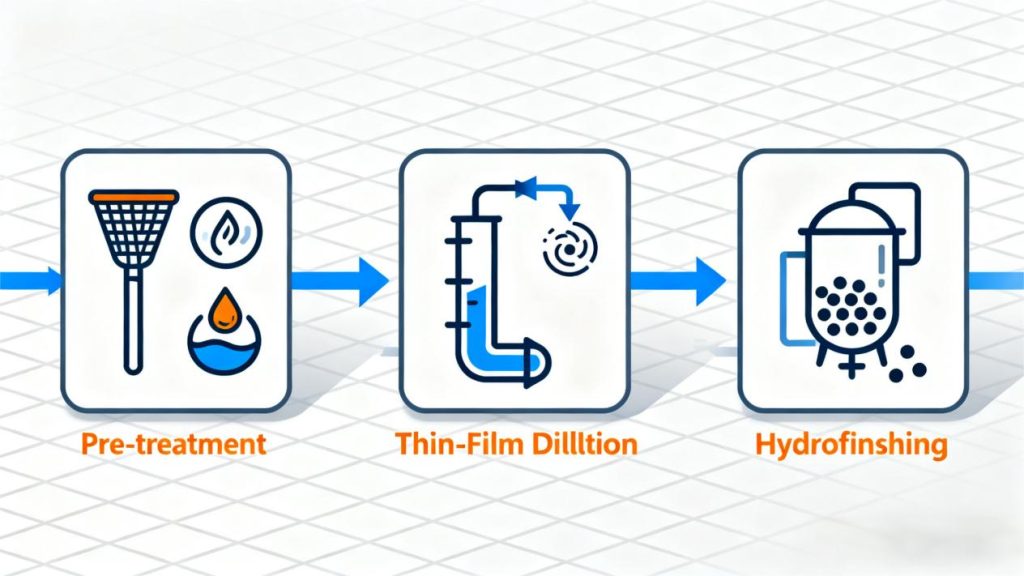

- The processes begin with pre-treatment. The aim here is to eliminate bulk contaminants. The used oil is allowed to pass through centrifuges or settling tanks, which efficiently and effectively separate free water, dirt, and solid particulates. This initial purification is quite essential to protect the downstream equipment.

- Next comes Thin-Film Distillation. The pre-treated oil is heated in a vacuum, whereby the desirable oil fractions vaporize at lower temperatures without being cracked. This advanced evaporation technique separates the reusable lubricant hydrocarbons cleanly from heavier, unwanted components like asphaltics and tars.

- The final and most critical stage of the process is called Hydrofinishing. During this finishing step, hydrogen is fed into the distilled oil under high pressure and temperature with the help of a catalyst. This process saturates unstable molecules, removes residual sulfur and odors, and decidedly improves the color and stability of the oil. The result is a transparent, re-refined base oil of very high quality, which is now ready to be blended into new lubricants.

The pre-treatment, distillation, and hydrofinishing sequence is the technological base for modern industrial oil recycling, which efficiently closes the loop on a very valuable resource.

Top Industrial Used Oil Recycling Technologies You Should Know

Today, as the requirement for purity and efficiency increases, better technologies are developed to recycle industrial used oil. Here are the leading technologies in use today:

1. Vacuum Distillation with Hydrotreating

This is considered the gold standard of modern industrial oil recycling. It includes the distillation of the oil under a vacuum-something that permits lower operating temperatures, thus preserving its quality-followed by hydrotreating. The result of such treatment is almost indistinguishable from their virgin counterparts, with base oils coming out as Group II or even Group III. This technology boasts the highest recovery rate and product quality.

2. Thin-Film Evaporation

A special type of vacuum distillation in which oil is spread in a thin film over a heated surface, maximizing the surface area for evaporation and thus being highly efficient with minimal thermal stress on the oil. It is excellent for a wide variety of feedstocks and forms one of the core components of many advanced recycling plants.

3. Solvent Extraction

Special solvents, normally N-methylpyrrolidone or furfural, dissolve selectively the undesired components of the used oil, such as aromatic compounds and additives. The purified oil is then separated from the solvent, which is recovered and reused. This is effective for the production of very stable base oils.

3. Clay Percolation (Acid-Clay Treatment)

One of the older processes, it treats the feedstock with sulfuric acid to remove impurities, followed by a clay filter to absorb impurities. While effective, it produces substantial amounts of acidic sludge and spent clay as hazardous wastes. Because of environmental issues, the process is being phased out in favor of more modern, non-hazardous technologies such as hydrotreating.

How to Choose the Right Industrial Oil Recycling Technology

The selection of the most suitable industrial oil recycling technology will depend on your specific operational, environmental, and economic facility needs. Each of these recycling methods offers unique advantages; understanding the differences between them is vital to get the best balance between performance, cost, and sustainability.

1. Analyze Your Oil Type and Contamination Level

Begin by evaluating the kinds of oils you deal with, whether lubricants, hydraulic oils, or cutting fluids, and the level of contamination.

Lightly contaminated oils may only need physical separation or membrane filtration.

The more degraded or contaminated an oil is, the more sophisticated the techniques required may be, such as hydrotreating or solvent re-refining. Matching the technology to the characteristics of your oil ensures the best recovery and quality of the recycled product.

2. Assess Quality Requirements and End Use

The desired quality of the recycled oil plays a major role in technology selection.

Investment in high-purity processes like vacuum distillation or hydrotreating will pay off better in the long run if the final product is to be reused in high-performance machinery or resold as base oil.

For less demanding applications, more basic reconditioning may be adequate. Setting clear quality targets early on streamlines your choice of technology.

3. Consider Budget, Scale, and Return on Investment

Each of these industrial used oil recycling technologies has its applicability determined directly by your budget and facility size.

Hydrotreating systems offer high yields but are more expensive to establish.

The quality vs. cost trade-off is reasonable with vacuum distillation and clay polishing.

Because modular filtration systems can be scaled gradually, they are ideal for mid-size operations. Calculating the payback period and possible savings from reduced oil purchases will provide a clear justification for your investment.

4. Ensure Compliance and Environmental Responsibility

Waste oil management regulatory standards vary greatly by region and are increasingly strict. Choosing a recycling technology that meets or exceeds local environmental regulations protects your business from both legal and reputational perspectives. Besides, technologies that reduce chemical waste, emissions, and energy use help your company achieve ESG and sustainability commitments.

Conclusion

But selecting the correct recycling solution involves more than just simple compliance; it’s about creating long-term value for operations. Whether it’s upgrading existing systems or looking into a customized recycling solution, experienced professionals can make all the difference in realizing dependable performance and consistent oil quality.

YANGJIANG specializes in customized industrial oil recycling solutions according to the customers’ operational goals and environmental commitments.

Contact us today to learn how our technologies can help you recover more value from used oil and take your sustainability strategy to the next level.

Recommended Products