Solvent extraction is a prominent industrial procedure that is utilized in numerous industries for purifying and separating chemical compounds. The most important application is in petrochemical refining.

Raw petroleum obtained from the earth is riddled with impurities and contaminants. It is cleaned first before processing into useful products. Solvent extraction plays an important role in this cleaning process, efficiently removing unwanted constituents and helping recover useful elements in conjunction with special solvents.

This efficient and scalable process not only enhances product purity but also supports sustainability via resource recovery.

Basics of Solvent Extraction

Solvent extraction refers to the selective elimination of unwanted components such as aromatics, resins, and other contaminants that confer stability, color, and performance problems onto the end product.

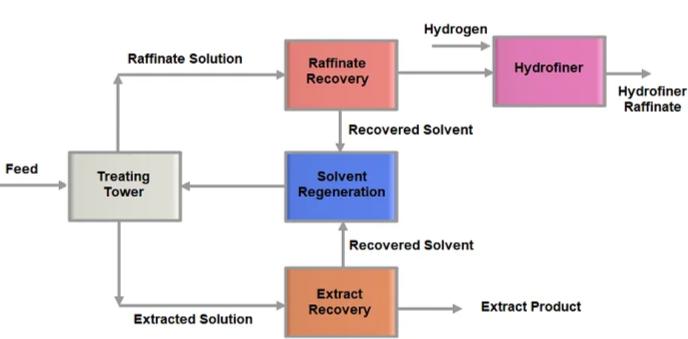

The process begins by mixing the crude or lightly refined oil with a specific solvent, such as furfural, N-methyl-2-pyrrolidone (NMP), or phenol, which selectively solubilizes the unwanted substances. The mixture is then exposed to separation, leaving the purified base oil behind. The solvent, which has been contaminated with impurities, is recovered through distillation or other recovery processes so that it may be reused for subsequent batches.

Solvent extraction is also extremely efficient to produce lubricant-grade base oils since it enhances viscosity index, oxidation stability, and low-temperature properties. Being precise and selective, it is the first choice of refiners seeking high-quality and uniform base oils.

Fundamentals of Solvent Distillation

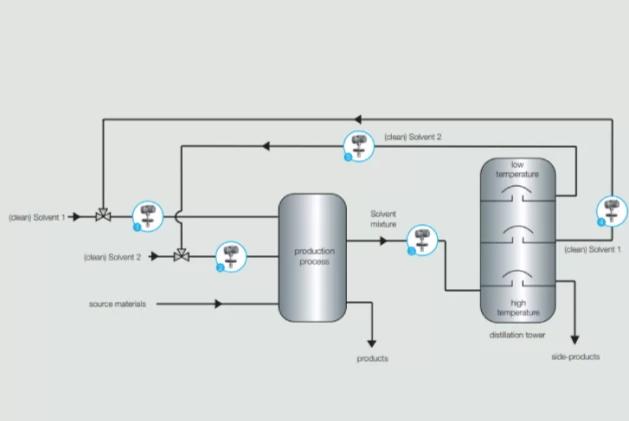

Solvent distillation is a refining technique in which crude or partially refined oil components are distilled from one another based on variations in their boiling points. In solvent distillation, the oil is first blended with a suitable solvent that specifically reduces the boiling point of certain fractions. The blend is then subjected to controlled heating, which results in the evaporation of volatile components while the heavy base oil remains in the liquid state. The solvent and impurities are vaporized and condensed in a different portion, such that the solvent can be recovered and reused.

This is used heavily for the removal of light hydrocarbons, residual solvents, and other low-boiling impurities from base oils. Although it is simpler in character than solvent extraction and requires fewer facilities to handle chemicals, it is more energy-intensive due to the requirements for heating. Solvent distillation is particularly effective in the early stages of petroleum refining, such that feedstock is purified further and the ultimate base oil quality is improved.

Solvent Extraction vs. Solvent Distillation

In petroleum refining, both solvent distillation and solvent extraction are routine operations to purify base oils, but they operate on different mechanisms and are optimized for different applications.

- Solvent extraction is mainly used to drive out undesirable compounds such as aromatics, resins, and waxes from crude or lightly processed oil. Solvent extraction works very well with oils that require stringent performance specifications but usually entails more advanced equipment and higher operating costs.

- Yet, solvent distillation separates on the basis of boiling point differences in components. While distillation is simpler and simpler to operate, it is generally less selective and more energy-intensive and hence better suited for pre-treating crude oils or general refining.

| Feature | Solvent Extraction | Solvent Distillation |

| Principle | Selective removal of impurities | Separation based on boiling points |

| Purity | High, ideal for lubricant-grade oils | Moderate, suitable for general refining |

| Efficiency | High, precise control | Moderate, less selective |

| Energy Consumption | Lower | Higher due to heating requirements |

| Cost | Higher initial investment | Lower initial investment |

| Typical Applications | High-viscosity base oils, specialty lubricants | Crude pre-treatment, light oils, general refining |

| Environmental Impact | Solvent recovery needed | Energy-intensive, solvent recycling required |

Applications in Petroleum Refining

- Solvent processes play a significant role in petroleum refining for product quality enhancement to industry specifications. Solvent extraction finds widespread application in the production of high-quality lubricating oils, transformer oils, and specialty base oils that demand excellent thermal stability, oxidation resistance, and tailored viscosity. It finds maximum application in the refining of heavier fractions where selective removal of aromatics and impurities is required to provide premium oil performance.

- Solvent distillation is, nevertheless, more frequently used in initial refining operations to strip light hydrocarbons, excess solvents, and low-boiling impurities from crude or partially refined oils. This yields cleaner feedstock for subsequent operations, such as hydrogenation or dewaxing, and improves overall refinery efficiency.

- Besides base oils, both procedures are also utilized to produce process oils, insulating oils, and chemical intermediates. By using solvent extraction or distillation strategically in a refinery, operators can optimize yield, reduce processing time, and provide consistent product quality, making these procedures valuable tools in modern petroleum processing.

How Modern Equipment Enhances the Solvent Extraction Process?

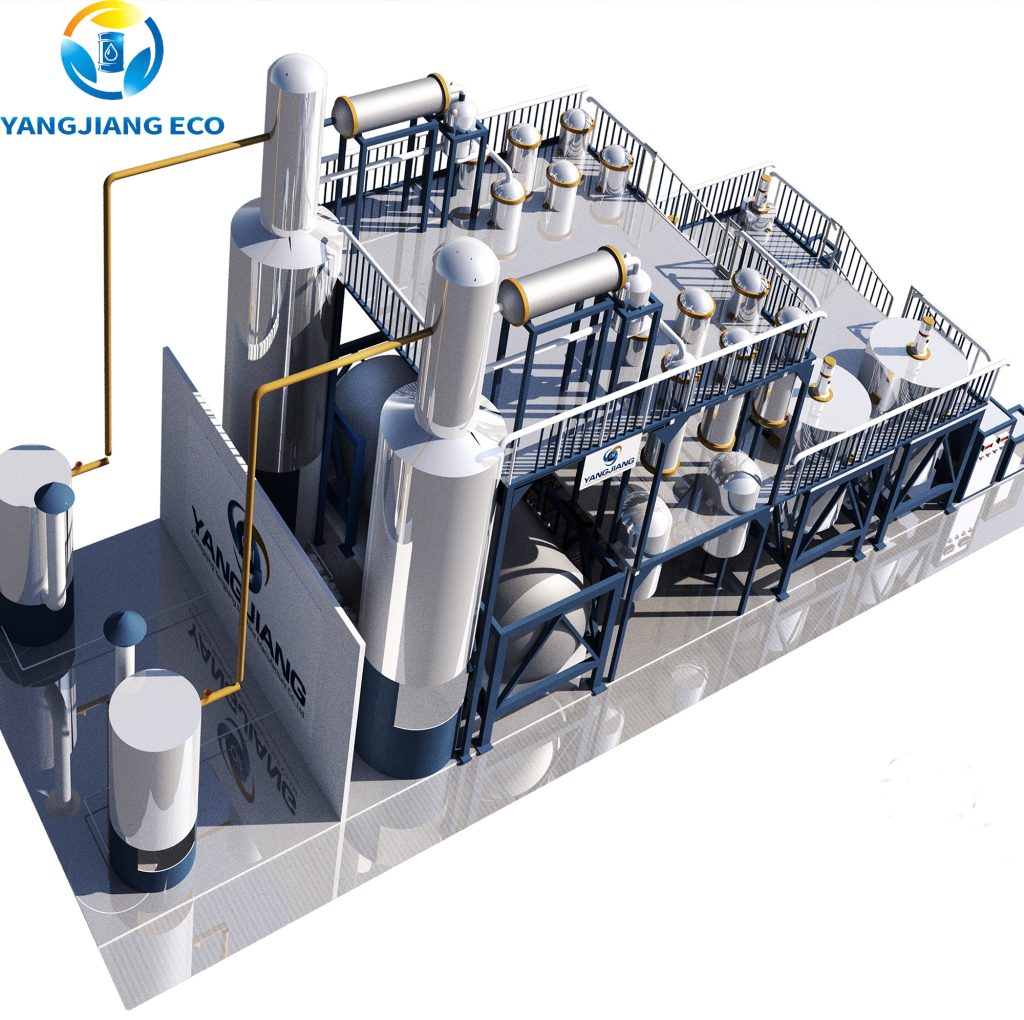

In petroleum refining, optimal production of high-quality base oils is always the number-one goal. Although solvent extraction is a proven technique, the result that you obtain basically depends on the machinery you use. Cutting-edge base oil solvent extraction machinery can simplify the process and make it more reliable so that refineries can maximize yield and product quality without excess complexity.

- Consistent High Purity: Enhanced temperature control, solvent-to-oil ratio, and processing time ensure consistent, high-quality base oils.

- Smart Solvent Recovery: Enhanced designs allow for more efficient reuse of solvents, saving cost as well as resources.

- Energy Savings: Enhanced operations reduce energy consumption while ensuring performance levels.

- Durable and Reliable: Built to withstand repetitive industrial use, these machines are long-lasting and hardy.

Through the use of state-of-the-art solvent extraction equipment, refineries can do more with less work. Investment in solid, high-capacity machines not only increases production but makes it possible to deliver the same quality consistently—a precious benefit in today’s competitive marketplace.

Want to invest base oil solvent extraction machine? Contact us now for more information!

Recommended Products