Base oil is a crucial component in the production of lubricants, serving as the primary ingredient in engine oils, industrial lubricants, and hydraulic fluids. The process of refining base oil is intricate and involves several stages to ensure that the end product meets the required performance standards. One of the most important processes in refining base oil is solvent extraction, which involves the use of specialized machines designed to enhance the purity and quality of the base oil. This article explores the role of solvent extraction machines in base oil production and their importance in the overall refining process.

Understanding Base Oil and Its Production Process

Base oil serves as the foundational ingredient in lubricants, making up the majority of the formulation in products such as engine oils, gear oils, and hydraulic fluids. Its quality directly impacts the performance, efficiency, and longevity of engines and machinery. Understanding how base oil is produced is key to appreciating the role of refining technologies—especially solvent extraction—in enhancing its properties.

The base oil production process typically begins with crude oil and involves several critical refining stages:

- Atmospheric and Vacuum Distillation: To start production of base oil, atmospheric and vacuum distillation processes must first separate crude into various fractions based on boiling points; heavier fractions that feature higher molecular weight are ideal candidates.

- Hydroprocessing (Hydrotreating or Hydrocracking): Distillates may undergo hydroprocessing to enhance both their quality and stability, with hydrogen introduced under high pressure and temperature to remove impurities like sulfur, nitrogen, and unsaturated hydrocarbons from them. Hydrocracking – an advanced version of this process, which involves breaking large molecules down into more manageable molecules, leaving behind clearer and more stable base oils than before.

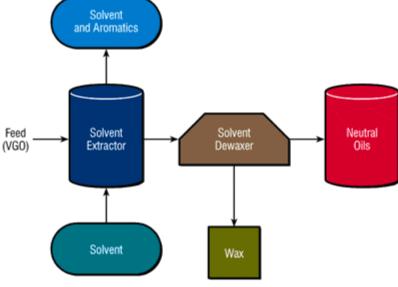

- Solvent Extraction: Even after distillation and hydroprocessing have taken place, certain unwanted aromatic compounds and contaminants remain. Solvent extraction can be used to selectively extract these impurities, thereby significantly improving base oil performance characteristics such as viscosity index, oxidation stability, and low-temperature fluidity.

- Finishing Processes: Additional refinement steps, such as dewaxing and clay treatment,t may also be implemented to further increase pour point and remove residual impurities, thus producing an ideal base oil suitable for further blending into lubricants.

Through this multi-step refining journey, raw crude oil is transformed into high-quality base oils that meet the demanding requirements of modern lubrication systems. Among these stages, solvent extraction plays a pivotal role in delivering the purity and performance required in today’s lubricant formulations.

The Importance of Solvent Extraction in Base Oil Refining

Solvent extraction is an invaluable method in base oil refining, offering powerful purification to improve the performance of lubricants. While simple distillation only separates components by boiling point separation, solvent extraction targets and dissolves specific impurities such as aromatics, sulfur, and nitrogen–known to cause sludge formation, oxidation or poor viscosity stability–directly for improved viscosity stability and viscosity performance.

Why Refineries Turn to Solvent Extraction

- Boosts Lubricant Quality – By stripping out unstable molecules, it produces cleaner, more durable base oils, essential for high-performance engine oils and industrial lubricants.

- Increases Viscosity Index (VI) – A higher VI means the oil maintains optimal thickness across temperature extremes, critical for modern engines.

- Reduces Environmental Impact – Lower sulfur and aromatic content align with strict emissions regulations (e.g., API Group II/III standards).

- Improves Cost Efficiency – Recovering and recycling solvents cuts operational expenses while maximizing yield.

Without solvent extraction, base oils would retain impurities, leading to faster degradation, increased engine wear, and higher maintenance costs. As the demand for premium lubricants grows, this process remains indispensable for refineries aiming to produce superior, sustainable base oils.

How Solvent Extraction Machines Work

Solvent extraction machines are engineered to remove unwanted impurities from base oil using selective solvents in a carefully controlled process. Their primary goal is to isolate and extract harmful or performance-reducing compounds, such as aromatics and sulfur, while preserving the desired oil components. Here’s a step-by-step look at how these machines operate:

- Solvent Mixing: To start this process, the base oil is mixed with an appropriate solvent such as furfural, phenol, or N-methyl-2-pyrrolidone (NMP). These solvents have been chosen based on their ability to selectively dissolve certain impurities found in the oil.

- Selective Dissolution: As the solvent blends with oil, it works to selectively dissolve undesirable components like aromatics and sulfur compounds, as these contaminants are more soluble than their equivalents in oil, which allows for efficient separation.

- Phase Separation: Once the solvent has taken up all the impurities in its solution, it is either left to settle naturally or passed through separation equipment in order to separate out the solvent-rich phase that contains impurities from the purified oil phase. Gravity settling, centrifugation, or coalescing filters may further enhance this separation.

- Solvent Recovery: After extracting impurities, the solvent is transported to a recovery unit for separation using distillation or evaporation. Once purified and recycled back into the process, making this operation both cost-effective and environmentally friendly.

- Final Product Collection: After separation and solvent removal, the purified base oil that has been freed of performance-hijacking compounds is collected. Depending on its grade and application requirements, further refining steps such as dewaxing or hydrofinishing may take place before final product collection.

Solvent extraction machines are highly efficient and adaptable machines, enabling producers to produce consistent, high-purity base oils suitable for a range of lubricant formulations. Their precision and ability to recycle solvents make them essential components in modern base oil refining.

Types of Solvent Extraction Machines and Technologies

At modern refineries, selecting an efficient solvent extraction technology is crucial to producing base oil efficiently. Different systems exist tailored specifically for specific feedstock characteristics and production demands.

1. Countercurrent Extraction Towers

Vertical column systems in which oil and solvent flow in opposite directions feature multiple contact stages for thorough impurity removal, making them suitable for continuous, large-volume processing.

2. Mixer-Settler Extractors

These hybrid extraction devices combine mechanical mixing with gravity separation for precise control over extraction parameters.

3. Annular Chromatography Systems

Use rotating cylindrical beds for continuous separation with superior selectivity of complex mixtures and the recovery of aromatic byproducts at high value.

4. Supercritical Fluid Extractors

While CO2 or other fluids in a supercritical state provide extraction services, other processes utilize CO2 or similar fluids under supercritical state and extract valuable aromatic byproducts that would not otherwise be recovered.

Solvent residues should not remain after the separation of liquid wastes from solid wastes.

As premium base oil production becomes ever more prevalent, innovative technologies such as membrane-assisted solvent extraction and microwave-enhanced processes are increasing production efficiencies further. These breakthroughs reduce energy usage while simultaneously improving extraction precision, both key elements in today’s highly competitive lubricant marketplace.

Wrapping Up

Solvent extraction machines are indispensable in base oil refining, ensuring the removal of impurities and the production of high-performance lubricants. As demand for Group II and III base oils grows, advancements in solvent extraction technology will continue to play a key role in the industry.

Investing in modern solvent extraction systems is a smart and sustainable choice for refineries looking to improve yield, reduce waste, and meet environmental standards.

Need to know more about base oil solvent extraction plant? Reach us now!

Recommended Products