Oil re-refining plants have emerged as essential tools in meeting rising environmental needs and carbon reduction goals by turning used oil into high-grade base oil that extends its shelf life while conserving natural resources. We examine their contribution to circular economy as well as their economic and ecological advantages in this article.

What is Oil Re-Refining?

Oil Re-refining is an innovative recycling method that transforms used lubricating oil into high-grade base oil that meets or surpasses industry standards. Re-refining restores used oil back to its original condition through rigorous purification, returning it closer to virgin grade than simple recycling can do. Instead of simply recycling used oil to lower-grade applications like fuel use, re-refining restores it back into its original form by eliminating contaminants like dirt, metals, and chemical additives while meeting or exceeding industry standards with results close to virgin-grade oil production.

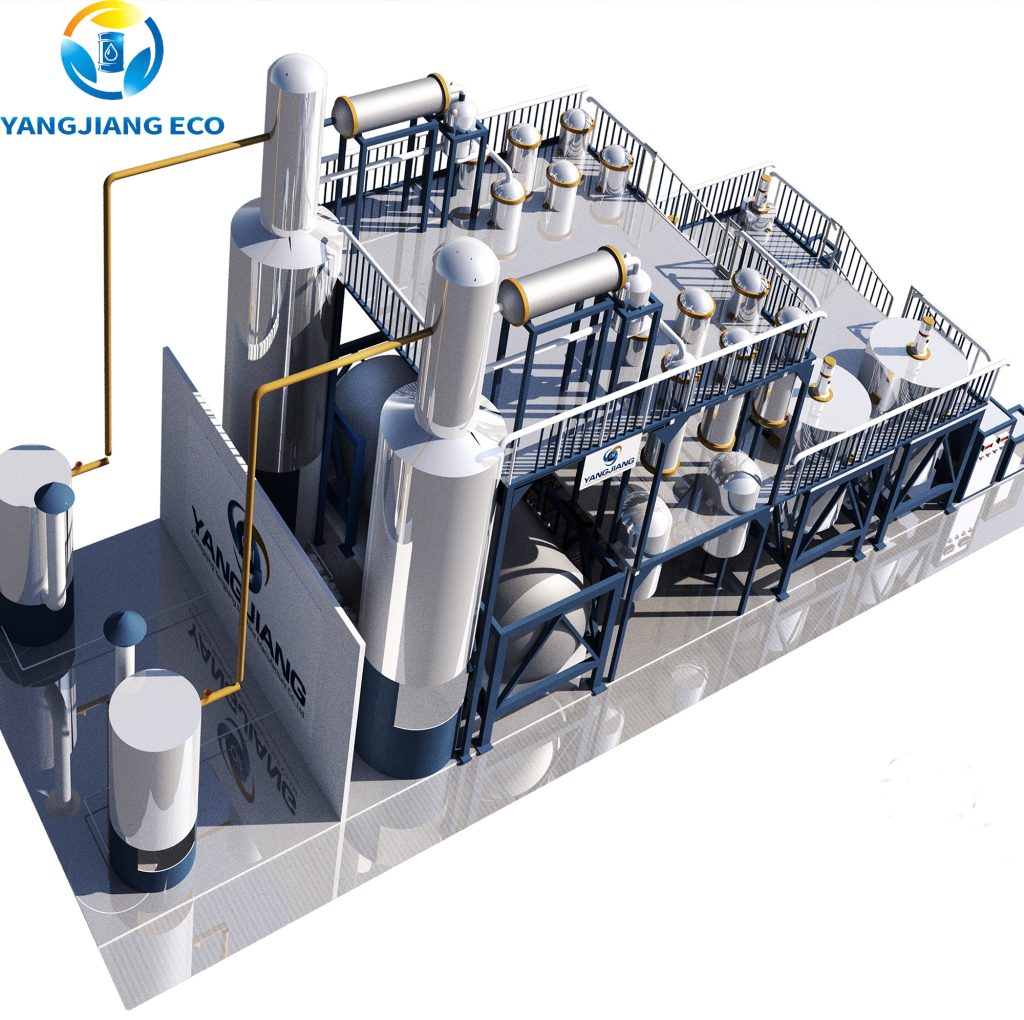

Modern oil re-refining plants employ advanced technologies like distillation, hydrotreatment, and filtration to produce products with performance comparable to newly refined oil. Refinery provides an economical and sustainable option that reduces crude oil extraction while decreasing hazardous waste generation.

By opting for re-refined oil, industries and consumers support a circular economy where resources are reused instead of wasted, conserving natural reserves while significantly cutting carbon emissions compared to conventional oil production methods. Re-refining has quickly become one of the key solutions for sustainable lubrication as environmental regulations tighten further.

How to Get Re-Refined Oil?

Re-refined oil offers an eco-friendly alternative to conventional lubricants while maintaining the same high performance. If you’re looking to switch to sustainable oil solutions, here’s how you can obtain re-refined oil:

1. Purchase from Authorized Distributors

Many lubricant suppliers now offer re-refined base oils that meet industry standards. Look for:

- API (American Petroleum Institute) certified re-refined oils

- ISO-compliant products

- Eco-label certifications (such as the EU Ecolabel or Blue Angel)

Major oil brands and specialty lubricant companies distribute re-refined motor oils, hydraulic fluids, and industrial lubricants.

- Purchase from Oil Re-refining Plants

Some oil refinery plants offer direct sales to businesses and bulk buyers – ideal for fleet operators needing large volumes of engine oil as well as industrial facilities requiring eco-friendly lubricants. This option may offer further savings.

Government and municipal programs promote green procurement.

3. Get Involved With Used Oil Collection Programs

Many regions offer used oil collection initiatives where both businesses and residents alike can drop off used oil at designated recycling centers while receiving incentives (discounts on future re-refined purchases in some instances) for doing so.

Join closed-loop recycling by making sure used oil is recycled back into its form of origin.

4. Investigate Government and Industry Initiatives

Government and environmental agencies often promote re-refined oil through: Tax credits for businesses using sustainable lubricants, Procurement policies that support such products Awareness campaigns on its benefits.

By choosing re-refined oil, you contribute to a circular economy while maintaining high-performance lubrication for engines and machinery.

How the Oil Re-Refining Process Works

The oil re-refining process is a sophisticated, multi-stage procedure designed to transform used oil into premium-quality base oil.

- It begins with collection and pre-treatment, where used oil is gathered and filtered to eliminate water, sludge, and heavy particulate matter. Next, the oil undergoes vacuum distillation, a critical step that separates different hydrocarbon fractions under reduced pressure, minimizing thermal degradation.

- After distillation, the process moves on to hydrotreating, where hydrogen at high pressure and temperature is applied at great height to remove sulfur, nitrogen, and other impurities that remain. This step greatly enhances color stability, stability, oxidation resistance, as well as performance properties of oil. Sometimes, solvent extraction may also be utilized to remove unwanted aromatic compounds for improved performance properties of an oil product.

- Subsequent dewaxing and fractionation processes further refine the oil to meet specific viscosity specifications, before being blended with additives to produce OEM and industry standards-compliant lubricants that meet or surpass them. This entire cycle not only rejuvenates used oil, but it also contributes to modern sustainable goals by decreasing waste while conserving resources.

Importance of Oil Re-refining Plant

Oil re-refining plants play an indispensable part in creating a more environmentally sustainable future by recycling waste oil into valuable resources and protecting our planet from environmental contamination by recycling used motor oil and industrial lubricant safely instead of simply being dumped or burned away.

Modern re-refining plants use advanced technology to restore used oil to its original quality, producing base oils that meet or surpass virgin oil specifications. This process reduces dependence on crude oil extraction while cutting carbon emissions by as much as 85% when compared with traditional refining.

- Beyond environmental benefits, these plants create economic value by:

- Generating high-quality lubricants at competitive prices

- Supporting green jobs in waste collection and processing

- Helping industries meet sustainability targets

By maintaining closed-loop recycling systems, oil re-refining plants demonstrate how industrial waste can be converted into premium products, making them essential for both ecological protection and resource conservation.

Economic and Environmental Advantages of Oil Re-Refining

Oil Re-refining offers both economic and environmental advantages over traditional methods for disposing of and refining used oil, making it a sustainable alternative. Re-refining has become essential to creating circular economies. Industries and governments worldwide strive to reduce waste while minimizing carbon emissions; oil re-refining has emerged as a solution.

Re-refining oil significantly lowers environmental costs by significantly decreasing demand for crude oil extraction, refining, and transportation. Improper disposal can pose severe ecological hazards; using this approach reduces greenhouse gas emissions up to 80% compared to refining crude oil directly; more energy and water are saved during this process, contributing towards reduced environmental degradation while contributing towards climate change mitigation efforts.

An oil refining plant plays a significant role in diverting millions of gallons of used oil away from landfills and waterways every year, saving both landfill space and contributing to global sustainability goals. Through their closed-loop system, waste oil is not simply dumped but transformed into high-quality base oil, which is ready for reuse, further decreasing overall waste generation while supporting global sustainability objectives.

On the economic side, re-refining presents a cost-effective solution for both governments and private industries. Operating an oil re refining plant creates jobs in collection, processing, quality assurance, and distribution. It also reduces dependence on volatile crude oil markets, stabilizing prices and lowering operational costs for companies that rely heavily on lubricants and fuels.

In addition, re-refined oil performs comparably to virgin base oil, providing high quality at a lower price. This affordability makes it attractive to consumers and industries alike, encouraging widespread adoption and further driving demand for sustainable practices.

In summary, oil re refining is more than just waste management—it’s a smart economic investment and a responsible environmental strategy for a cleaner, more efficient future.

Applications of Re-Refined Base Oil

Re-refined base oil matches the quality of virgin oil, making it suitable for diverse industrial and automotive uses. Here are the key applications:

1. Automotive Engine Oils

Re-refined base oil is extensively used in passenger car motor oils (PCMO) and heavy-duty diesel engine oils. It undergoes stringent refining and additive treatment to meet API/ACEA specifications, ensuring optimal engine protection, wear resistance, and thermal stability. Major lubricant brands now blend re-refined oil into their products, proving its performance parity with conventional oils.

2. Industrial Lubricants & Hydraulic Fluids

Manufacturers use re-refined base oil to produce:

- Hydraulic fluids for construction and agricultural machinery

- Gear oils for wind turbines and industrial gearboxes

- Compressor oils for air and gas systems

These applications benefit from re-refined oil’s high viscosity index, oxidation resistance, and anti-wear properties, reducing equipment maintenance costs.

3. Marine and Railroad Lubricants

In marine engines and rail systems, re-refined oil provides:

- Corrosion protection in high-moisture environments

- Thermal stability under extreme operating temperatures

Shipping companies and rail operators adopt re-refined lubricants to meet environmental regulations while maintaining engine efficiency.

4. Metalworking & Process Oils

Re-refined base oil serves as a key component in:

- Metal stamping and cutting fluids

- Quenching oils for heat treatment

- Industrial process oils

Its purity and consistency ensure smooth manufacturing operations while minimizing waste oil disposal.

By integrating re-refined oil into these applications, industries achieve sustainability goals without compromising performance. As technology advances, its adoption continues to expand across sectors.

Conclusion

Oil re-refining is an eco-friendly solution that cuts waste, carbon emissions, and supports circular economies. By selecting re-refined oil from advanced oil refinery plants, businesses and consumers contribute to environmental preservation while taking advantage of cost-effective, high-performance lubricants produced from this cutting-edge technology. Adopting it now to build a greener tomorrow.

Recommended Products