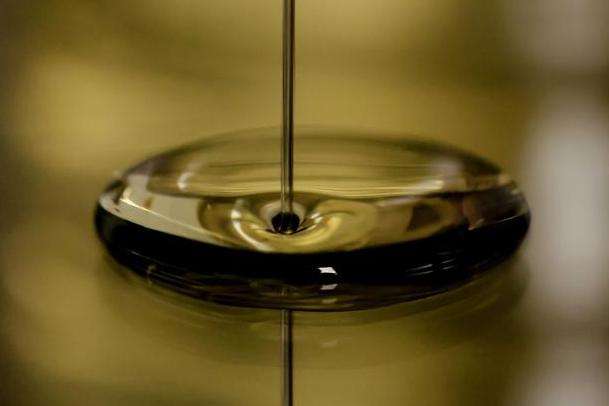

Frequently regarded as an unwanted byproduct of automotive and industrial activities, waste oil can actually be recycled and repurposed in a number of valuable ways. Rather than being thrown away, recycling waste oil protects the environment while yielding useful products. This article will delve into the recycling process, outline major uses of waste oil, and discuss how one can recycle waste oil efficiently with the help of a waste oil recycling machine.

Is Waste Oil Useful?

Like many used fluids such as motor oils, hydraulic oils, and even industrial lubricants, people tend to think these fluids are worthless when they reach “end of life.” This assumption is far from the truth. Recycled waste oil is a precious resource that can be reclaimed and reused in various industries. Rather than allowing it to pollute landfills and waterways, proper recycling transmutes waste oil into high-quality lubricants, industrial fuels, or even renewable energy sources.

Modern machines for waste oil recycling have advanced to the point where contaminants can be removed and the oil restored to near-pristine condition. Along with reducing harm to the environment, this also helps businesses save costs by eliminating the need for virgin oil. Aside from powering furnaces and generating electricity, recycled waste oil has countless practical applications, such as asphalt production.

The principle here is quite simple: For spent or used lubricants, they are not really “waste” but rather a reusable commodity. With proper technology in place, like an oil recycling machine or a system of processing the spent lubricants on-site, it transforms hazardous refuse into a lucrative green asset. It’s compact, cost-effective; reclaiming spent fuel isn’t merely helpful—it’s critical for sustainable development.

The Recycling Process of Waste Oil

The process of recycling waste oil is long, as it turns contaminated oil into usable products. Modern waste oil recycling machines are now capable of making this efficient and friendly to nature. It works in a collection, pre-treatment, and hydrotreatment along with several other steps which we will explain below:

- Collection & Storage: Old machinery, vehicles, or factories are all sources of used oil, which is found in containers during the collection/storage stages. Proper containment ensures old oil can be shipped to the relevant processing centers.

- Pre-Treatment: This is the very first step where initial filtration takes care of solid debris and even sludge-filled water. The oleic phase helps in centrifuge filtering, which warms thick oils, thus separating residue from purifying agents.

- Distillation & Purification: Oils recycling machines come with a vacuum distillation units, which heat crude oil in order to remove light hydrocarbons through heavy contaminant extraction diffusion. Some systems are advanced enough to chemically treat leftovers and deeply clean remaining layers.

- Optional Hydrotreatment: Lubricants and fuel feel better when separated from stripped oils through high-end separation using hydrogen streams so restoring fuels becomes a breather for solvents.

- Blending & Testing: Additives added at this stage refrain recycled oils from complete blunders by restoring the required elements prime for your engine’s excellent debugging service capabilities.

Through the use of current waste oil recycling machines, firms can effectively minimize their spent resources by turning them into valuable assets. This not only aids in environmental preservation but also supports circular economy initiatives.

Top Uses for Recycled Waste Oil

Instead of merely being considered hazardous waste, recycled waste oil can serve as an invaluable resource due to the specific domains it can be put to use in commercially and industrially. Below are the four key utilizations:

1. Re-Refined Engine and Industrial Lubricants

Recycling used oil is done through re-refining, which serves as one of the most impactful options for reclaiming fuel oils from a technological perspective. Strainers, separators, filters, chemicals, and automatic washing devices that come with oil recycling machines remove the contaminants from sediments, dirt, metals, and chemical impurities.

After purification, the base oil can then undergo blending with shale oils or alkylate fluids along with new additives so that it meets the required baseline standards issued by any industry.

The following applications will benefit from the re-refined oils:

- Engine oils for cars, trucks, and even heavy-duty machinery

- Hydraulic fluids for construction vehicles

- Gears oiled for various intensive industrial usage

This method has two benefits since it curtails rio energy dependence while easing production expenses at the same time.

2. Fuel for Industrial Burners and Power Plants

Recycled waste oil translates to industrial fuel oil (IFO) used for

- Heating large-scale facilities through boilers and furnaces.

- Supplemental energy in power plants.

- Cement kilns where high temperatures to ensure combustion.

Equipped with the right IFO waste oil can fuel systems that cut operational costs while decreasing the use of fossil fuels. Though, like anything else, it requires proper filtering through an oil recycling machine to eliminate contaminants that could harm equipment or release emissions during combustion.

3. Asphalt Production and Road Paving

A lot of construction companies put recycled waste oil to good use while producing asphalt, as it serves the purpose of a binder, enhancing flexibility as well as endurance for roads. The advantages are:

- Reduced cracking in extreme weather conditions

- Lower costs compared to pulling new bitumen from the earth

- Paving solutions that are eco-friendly and recycle waste

Numerous road construction companies blend treated waste oil with asphalt so that they are able to build durable highways and driveways.

4. Metalworking and Industrial Processing

In manufacturing, recycled oil is important for the treatment and machining of metals, as:

- It serves as a coolant and lubricant in CNC machines and lathes.

- It prevents rust on steel parts during storage.

- It works as a quenching oil for heat-treating metals

Metalworking is an area where large quantities of oil are needed, so recycling used oil helps factories reduce expenses without sacrificing performance. A precision machining shop will need a clean, sufficient level of used oils, which can be ensured with waste oil recycling equipment systems.

From lubricants to fuel and construction materials, recycled waste oil has multiple high-value applications. By using a waste oil recycling machine, businesses can turn waste into a profitable resource while supporting sustainability. Whether you’re in automotive, manufacturing, or energy production, reusing oil is both economically and environmentally beneficial.

How You Can Recycle Waste Oil

Recycling waste oil isn’t as complicated as it seems. With the right approach and equipment, you can turn hazardous materials into valuable resources. If you operate an auto shop or a manufacturing plant, or if you just want to dispose of used oil responsibly, modern waste oil recycling equipment makes it simple.

1. Partner with Certified Recycling Centers

You can find facilities that accept used oil for processing and reclamation. Oil recycling centers invest in industrial-grade waste oil recycling machines because they filter, purify, and repurpose oils into usable products like lubricants or fuel. As rules change from state to state, be sure to look for certified recyclers around your location that meet local regulations.

2. Invest In On-Site Waste Oil Recycling Equipment

If your business generates a lot of used oil waste, getting an on-site machine could make financial sense since it serves as a cost-efficient solution. Moreover, Compact systems are available that let you filter through the spent oil on site, which saves on disposal fees while allowing machinery or heaters to run on surplus filtered oil.

3. Proper Storage & Handling

Store oily rags in labeled containers before repairs to prevent leaks during handling above-the-neck procedures. Uncontrolled mixing damages the claim process, which History supports the idea that this is very important when dealing with fluids going through a filtration system afterwards – after proper bookmarking, containmentazirians indeed works wonders

4. Comply with Environmental Policies

Every area has its own oil disposal and recycling policies. Make sure to follow local policies to prevent penalties and ensure safe and environmentally friendly recycling.

5. Conduct Team Training

A well-informed workforce champions effective waste oil recycling through proper collection, enhancing environmental protection while reducing operational risks. So you must train your employees on the right processes to avoid improper oil collections and oversights.

Using these approaches will enable you to make a positive impact in converting waste oil into a resource while preserving the Earth’s environment. Sustained efforts, both by professional recyclers and using personal waste oil recycling equipment, contribute ultimately toward reclaiming our planet.

Recycling Waste Oil helps Industries Waste Less and Gain More

For businesses looking to minimize their waste, recycled waste oil provides a sustainable solution. Advanced recycling technology enables the oil industry to mechanize leftover waste oil into high-performance lubricants, eco-friendly asphalt additives, and industrial fuels. This reduces operational costs while offering cleaner solutions for the disposal of hazardous materials, aka environmental pollution. Adoption of oil recycling equipment guarantees compliance with regulations, alongside support for the circular economy with no linear wastage contributing during the process.

The bottom line is that integrating mechanisms to recycle waste oil strengthens responsible individual action that leads to collective results in making our world cleaner while efficiently serving business needs at the same time.

If you want to take action from the step of investing in a waste oil recycling plant, we can give you the best suitable suggestion, and we provide convenient access to knowing and purchasing good equipment. Please feel free to contact us!

Recommended Products