Used engine oil is classified as hazardous waste because it has the potential to cause notable damage to the environment. With the appropriate recycling techniques, this waste oil has the potential to become a valuable resource, therefore reducing pollution while conserving natural resources at the same time. In this article, we will discuss the technologies, methods, and benefits of the recycling process of used engine oil.

Why Should Used Engine Oil Be Recycled?

Used engine oil stands as one of the most dangerous forms of waste if not properly managed. Its disposal, even in minute quantities, poses the risk of contaminating significant expanses of water and soil, endangering ecosystems and human health. Still, used engine oil is a waste product which, through proper recycling, allows base oil that can be retrieved and reused. Lowering the demand for virgin crude oil, recycling conserves non-renewable resources, reducing the greenhouse emissions captured during oil extraction and refining.

Used engine oil recycling also diminishes the need for costly disposal options like incineration or landfilling, both of which harm the environment. Oil is not discarded, but instead cleansed and restored to a reusable state, supporting waste. With the right-used engine oil recycling process and technology, waste can be transformed into lubricants, high quality fuels, or industrial oils. Therefore, recycling is not only an environmentally responsible action, but economically and industrially beneficial.

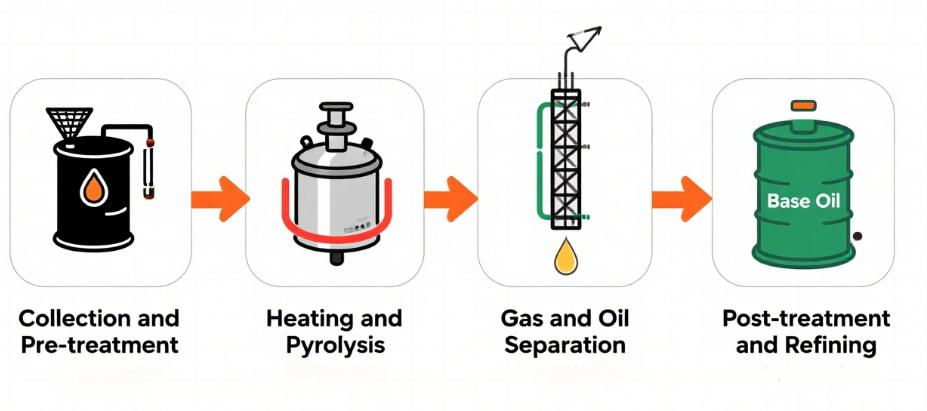

Process of Used Engine Oil Recycling

The recycling system for used engine oils is aimed at eliminating impurities and reclaiming the engine oils for efficient reuse, thus ensuring the oil’s operational characteristics restore its value. The vital objective in this process is attained when the base oil is reclaimed and the ecological footprint is reduced, thus thermal pyrolysis becomes the preferred technique due to its efficiency. This process is usually done in a used engine oil recycling pyrolysis plant.

- Collection and Pre treatment

The initial phase is focused on gathering used engine oil from automobile and industrial machinery service stations. The gathered oil typically contains a blend of water, sludge, heavy metals, carbon residues, and a mixture of various chemical additives. The oil is extracted from water and other additives through methods of filtration, sedimentation, and pre-treatment during recycling. This reduces the particles and water from the oil.

- Heating and Pyrolysis

The collected oil is treated and preheated. This pre-treated oil is now ready to be placed into the pyrolysis reactor where it will be heated to high temperatures (around 300 to 400 degrees Celsius) without the presence of oxygen. This will further break down the long chain hydrocarbons in the used oil to shorter chains. This converts the oil into gas, liquid fuels, and other solids. This process is efficient as no combustion occurs during this process.

- Gas and Oil Separation

During pyrolysis, the process releases vaporized hydrocarbons that travel through a cooling system, where they are transformed into various oil fractions, light fuel oil, and base oil. Separately collected non-condensable gases are often reused as fuel to heat the reactor, which increases the plant’s energy efficiency.

- Post-treatment and Refining

The oil can undergo further treatment through distillation or filtration to improve engine oil or industrial fuel. This further enhances its quality by increasing its viscosity and purity, which makes it suitable for reuse.

Advanced engine oil recycling transforms waste oil into reusable products and lessens environmental impact while promoting resource sustainability.

Main Used Engine Oil Recycling Technologies

The recycling of used motor oils involves sophisticated technologies that strive to recover clean motor oils or fuel components with minimal contaminants. It revolves around a number of factors that include regulations of the environment, quality of output, and the volume of used oil and recycling capacity. The most commonly used and effective engine oils recycling technologies are:

- Vacuum Distillation

This method processes used engine oil by heating it under a vacuum, which lowers the boiling points of its components. Because it is done under lower temperatures, the possibility of thermal degradation is eliminated. The oil is separated into base oils, diesel fuel, and lighter hydrocarbons. In this method, water with light and heavy ends and some heavy metals are removed as well, which results in a clean base oil that can be blended with some lubricants.

- Technologies of Pyrolysis

Pyrolysis is best known for thermal breakdown (decomposition) in the absence of oxygen. For instance, Used engine oil can be heated to approximately 300 to 400 degrees Celsius. This will break the complex hydrocarbon molecules to simpler ones, which results in a mixture of liquid fuel, non-condensable gases, and solid residues (like carbon black or sludge). The liquid can then be processed into base oil as well as an industrial fuel, while the non-condensable liquid and the gases can be combusted to provide heat to the reactor, making the whole process eco-friendly.

- Hydro-Treating

Hydro treating, as a chemical process, is known for the application of Hydrogen gas at high RPM and temperature to remove sulfur, nitrogen, and any other contaminants from recycled oil. This process, alongside others, enhances the base oil color, stability, and quality. Like other chemical processes, Hydro treating is paired with vacuum chemical distillation to meet the set industrial standard for lubricants.

- Clay Treatment and Filtration

This procedure is the most efficient in the application of clay or adsorbent materials for the removal of color bodies, trace metals, and other fine impurities. Compared to other methods such as distillation or hydro treating, clay is less sophisticated; however remains efficient for refining the oil.

These technologies serve as the backbone of contemporary used engine oil recycling facilities, as they enable effective recovery while prioritizing safety for the environment.

Environmental and Economic Benefits

Recycling used engine oil is an important practice in waste management and conservation of resources because of its environmental and economic importance.

Environmental Protection

Environmental safety is at risk when used engine oil is disposed of carelessly since it is classified as hazardous waste. The environmental risk is dire because a single gallon of used oil has the potential to contaminate water in the range of a million gallons. Contamination of water has a far-reaching chain effect, and it is detrimental to marine life, soil, and groundwater. Through recycling, the oil can be processed and stripped of its hazardous contents ,such as heavy metals, carbon deposits, and chemical additives, thus minimizing further oil contamination.

Recycling waste oil to create products such as base oil and fuel cuts down on the need for further extracting and refining crude oil, which is a source of greenhouse gases and causes further destruction to the environment. Moreover, advanced technologies such as vacuum distillation and pyrolysis, which operate in a closed system, reducing air and water pollution while adhering to environmental standards and sustainability objectives, are a further boon.

Economic Benefits

Recycling used engine oil has substantial economic benefits. The retrieved base oil and fuels can be reintroduced into the market. This cuts down the need for virgin oils and lowers production costs for lubricants and industrial fuels. Businesses and governments no longer need to spend on waste disposal and environmental cleanup. Instead, they make profits, not only from the sale of recycled products, but also from cleaner recycling.

Recycling plants provide new local jobs and stimulate the clean technology sector. This also supports the circular economy, where waste becomes useful input. In addition, the energy spent on recycling oil is much less than the energy used to refine crude oil. It takes much less energy and resources to produce lubricants from recycled oil than from crude oil.

In essence, the benefits of used engine oil recycling extends to used oil recycling for the engine and oil lubricants. It is a pragmatic strategy for cleaner industrial production with reduced ecological footprints and provides a great cleaner eco-industrial production.

Recommended Products