Recycling waste oil to diesel fuel is no longer a green idea—but a realistic solution to help reduce pollution and create affordable energy. We’re a waste oil to diesel equipment manufacturer and supplier, specializing in providing innovative equipment and solutions that transform used engine oil, industrial lubricant, and even waste cooking oil into high-quality diesel fuel.

By being aware of the right types of waste oil and the best conversion methods, not only can individuals and companies save on fuel costs, but they can also help promote sustainable energy. In this post, we will guide you through the types of waste oil that can be transformed, the technology, and why investing in a waste oil-to-diesel machine is a good idea.

Can Waste Oil be Converted into Diesel Fuel?

Yes, waste oil can indeed be transformed into diesel fuel using high-technology industrial processes. Waste oil like used engine oil, industrial oils, and even waste cooking oil is a mixture of hydrocarbons that could be transformed into usable fuel. Effective conversion not only provides an economic energy source but also remedies the environmental concern surrounding the indiscriminate disposal of used oil.

The process is a process that eliminates contaminants, breaks down heavy hydrocarbon chains, and refines the end product to diesel fuel grade. There are advanced technologies that allow it to efficiently convert with few toxic byproducts, such as hydroprocessing, pyrolysis, and catalytic cracking. The quality of diesel produced is a match to normal diesel, with a property appropriate for generators, transportation, and industrial equipment.

As a professional waste oil to diesel machine supplier, our machinery provides high conversion rate efficiency, consistent fuel quality, and safe operation. Purchasing a waste oil to diesel system not only creates a sustainable energy loop but also provides companies with an opportunity to save fuel expenses and generate additional revenue from otherwise wasted oil. In practice, recycling used oil into diesel is a clean, environmentally friendly, and economically effective choice for companies and society as a whole.

What Kinds of Waste Oil Can Be Converted into Diesel

Not all waste oils are created equal when it comes to making diesel. The most suitable waste oil to make diesel is petroleum-based waste oil that is generated from industrial and motor processes. These kinds of oils have high amounts of hydrocarbons, the most crucial component necessary to make diesel fuel.

- Used Engine Oil is one of the most common sources. Collected from car service stations and workshops, it contains long-chain hydrocarbons that can be degraded easily and processed into diesel fuel. Filtration and pre-treatment must be carried out with caution to remove heavy metal impurities and other impurities.

- Lubricants from factories and heavy machinery, hydraulic oils, and industry are also good feedstock. They are usually more viscous and contain additives, but through effective pre-treatment and processing technology, they can yield excellent quality diesel fuel.

- Transformer Oil and Gear Oil are some of the specialty petroleum oil-based fluids that are recyclable. Though they contain advanced chemical additives, recent waste oil to diesel equipment can handle these oils safely and efficiently so that the resultant diesel is of standard quality.

Focusing on these oil-based waste oils creates a constant yield, lowers processing challenges, and allows industries to transform hazardous or costly-to-dispose oil into a profitable and renewable energy source.

How to Convert Waste Oil to Diesel?

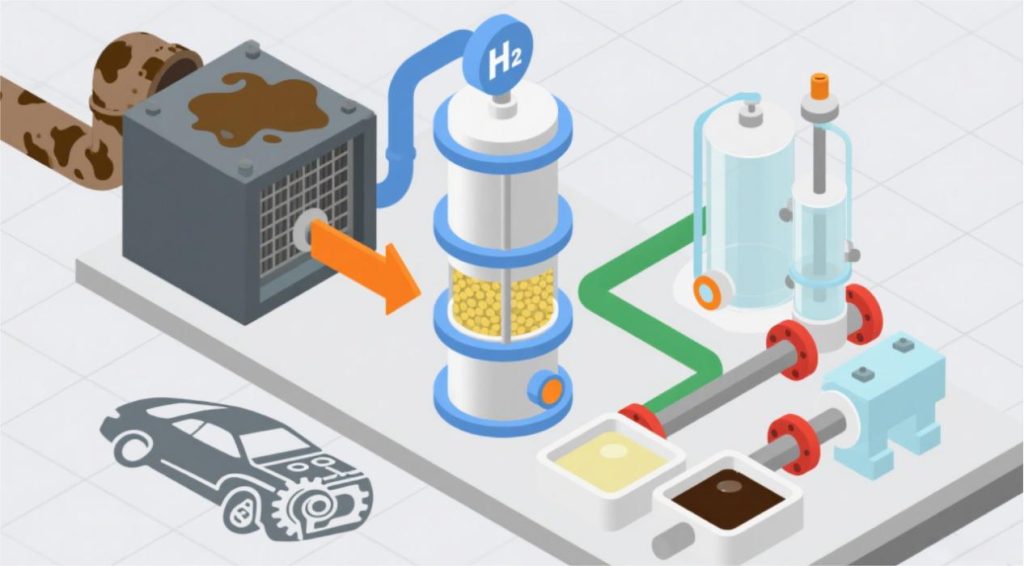

Changing waste oil into diesel fuel requires sophisticated processing techniques to remove heavy hydrocarbons and impurities. With various types of waste oil available, one can choose different methods for each to suit the desired output. The following are the methods that are largely used.

Hydroprocessing / Hydrocracking

Also known as Hydrocracking, Hydroprocessing is a catalytic chemical method of breaking long-chain hydrocarbons into lighter, diesel-range molecules using high-pressure hydrogen. Diesel fuel is free of sulfur, nitrogen, and other contaminants; therefore, hydroprocessing effectively hydrocracks the fuel receiving such treatment. Hydrocracking works well with waste oils with more intricate compositions, such as engine oils and lubricants. While it requires sophisticated equipment and strict operational controls, it produces high-quality subsidised fuel as the output.

Pyrolysis (Thermal Cracking)

This form of thermal treatment, pyrolysis, involves the heating of waste oil in the absence of oxygen. It is a form of thermal treatment that breaks down large hydrocarbons. It is one of the most efficient methods of waste oil to diesel pyrolysis. It is used in several waste oil to diesel machines, as it has a lower investment cost. In addition to diesel, the pyrolysis of waste oil produces byproducts such as carbon black and combustible gases. These byproducts can also be used in waste-to-energy recovery. Careful control of temperature and further waste oil filtration minimisation of combustibles, in this case, combustible waste oil needs to be controlled.

Solvent Extraction + Catalytic Cracking

This two-step process begins with the removal of impurities, sludge, and heavy particles that are present in the waste oil using special heavy-oil solvents. Withdrawn oil is then subjected to catalytic cracking, in which heavy hydrocarbons are broken down further using catalytic materials into diesel oil containing hydrocarbon fractions. This is especially suited for highly contaminated waste oils like used industrial lubricants. It also produces diesel with stable properties appropriate for storage and long-term use with minimal degradation.

Distillation and Blending

Distillation fractions treat waste oil by boiling point. The fraction that will become diesel range is then recovered and also treated or blended to meet diesel fuel specifications. While less complicated than hydrocracking or catalytic treatment, additional treatment could be required to reduce sulfur levels or viscosity. Distillation with blending is routinely applied in small-scale waste oil to diesel plants for economical fuel production.

Each process has strengths depending on feedstock type, investment, and quality of diesel to be specified. Good technology selection ensures maximum fuel yield, minimum environmental footprint, and reliable operation for commercial or industrial applications.

Why Use Waste Oil to Diesel Machine?

Having understood the types of waste oil that can be converted to make diesel and the technologies to achieve the conversion, it is clear why investing in a waste oil to diesel machine is a strategic step for industries and companies. The machines provide a turnkey solution for recycling petroleum-derived waste oils—used engine oil, industrial lubricants, and gear oils—to high-quality diesel fuel efficiently and safely.

- One of the main advantages is cost savings. With on-site waste oil conversion, companies can essentially reduce fuel purchase costs while, meanwhile, dispose of hazardous oil. Instead of paying for waste oil treatment or environmental fines, companies can generate viable diesel fuel and, in some cases, sell excess fuel or byproducts, an alternative source of income.

- Also, the advanced technologies such as pyrolysis, catalytic cracking, and hydroprocessing used in modern systems allow precise control over output, producing diesel that meets industrial specifications. This ensures reliability for generators, heavy machinery, or fleet vehicles.

- Ecologically, the use of waste oil to diesel machines helps in promoting sustainability since it recycles oil that would otherwise pollute land or water. It reduces dependence on traditional fossil fuels and assists in the development of a circular economy since it transforms industrial and automotive waste into fuel.

In short, a waste oil to diesel machine is not just a fuel-producing machine—it’s a comprehensive solution that bridges efficient waste oil management, cost savings, and clean energy production all in one system.

To Sum Up

Waste oil to diesel is a green and feasible option for industries requiring cheap energy and environmentally friendly waste disposal. With the appropriate selection of petroleum waste oil and superior technology such as hydrocracking, pyrolysis, or catalytic cracking, better quality diesel can be produced in an economical way. Not only does a waste oil to diesel machine save fuel costs and generate additional revenue, but it also has lower negative environmental effects. For enterprises that want to merge economic profit with sustainability, recycling waste oil into diesel fuel is a good, profitable, and environmentally friendly practice. If you have an interest in waste oil to diesel machine, welcome to contact us at any time!

Recommended Products