If you are in a business that generates a lot of used lubricating oil—from auto shops to large factories—you’ve likely had the issue of disposal. More significantly, you’ve probably asked a fundamental question:

Is there a more lucrative and responsible way to deal with this waste stream?

Can this waste be disposed of in a responsible, profitable, and efficient manner?

The answer is a definitive yes. The used lube oil recycling process is a modern and highly effective way of safely recovering and reusing an otherwise wasted resource. We have manufactured recycling plant equipment and understand recycling technology and its operational benefits to the customers we serve. Here, we will explain the entire process, its value, and the equipment that facilitates the process.

Is it Worthy to Recycle Used Lube Oil?

Recycling used lube oil presents two extraordinary opportunities: fulfilling one’s social responsibility and attaining commercial interests. Each liter of used oil has a recoverable portion of base oil that can be re-refined into a high-value oil product that can be used in the industrial sector and the automotive sector. Used oil does not need to become waste with the potential to harm the environment; it can become an effective and valuable product.

The following are the most important rationales for the recycling of used lube oil:

- National and Global Environmental Responsibilities: Protecting the environment and ecology is the primary reason for recycling.

- Reduction in Processing Costs: The financial benefits of recycling are quite high.

- Avoiding Environmental Fines: Compliance with recycling laws is a prerequisite to legally avoiding Eco-fines.

- Waste Recycling: It is the core of Resource Recovery and Gap Sustainability.

- Income Generation: The reprocessed oil is of high value commercially.

In conclusion, the commercial profit that lube recycling plants yield makes them economically viable and thus a valuable component in business strategizing. The increased profit margin is a true indicator of cost-effective operations.

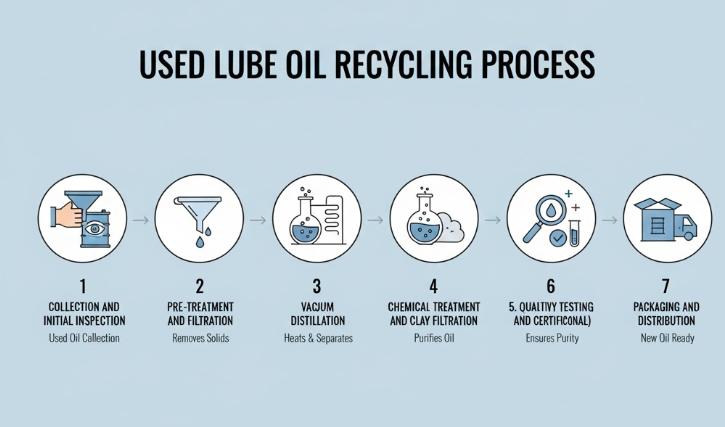

Steps Involved in the Used Lube Oil Recycling Process

Turning waste oil into quality base oil for reuse requires lube oil recycling to be done in highly structured sequences and steps. All steps in this process are essential. The quality and amount of the recycled product can be significantly impacted by the slightest inefficiencies.

1. Collection and Initial Inspection

Used oil from automotive workshops, industrial machinery, and factories includes collection and safe disposal contaminated by water, sludge, and extreme pollution. Storing oil in sealed containers that are labeled properly prevents further cross-contamination and contamination, and the oil can be readied for processing.

2. Pre-treatment and Filtration

Used oil pre-treatment steps include recycling.

- Settling: Allowing heavier sediments and particles to settle at the bottom of the storage tanks.

- Filtration: Elimination of the solid debris by the mechanical filter.

- Water Separation: Elimination of free water, which can cause foaming and later corrosion.

This is done to improve the oil that is about to enter the main recycling process to the desired quality and efficiency.

- Vacuum Distillation

Every part of the recycling process uses Distillation. Base oil Vacuum Distillation units separate usable base oil from contaminants. Lower temperatures reduce heating oil evaporating Impurities, which minimizes thermal degradation. This stage effectively removes volatile compounds, residual fuel, and light ends, leaving behind purified base oil.

- Chemical Treatment and Clay Filtration

The oil’s subsequent process is chemical treatment, which neutralizes the oil’s acids. Chemical treatment also removes the last remaining heavy metals and aromatic compounds. Clay filtration helps by removing color, stability and impurities, and viscosity gradients. The result is a purified base oil that is ready for blending or direct reuse.

- Additive Blending (Optional)

To build certain oils for intended applications, performance-enhancing additives may be added. For example, high-performance motor oil or industrial lubricants may be created by adding antioxidants, anti-wear agents, and detergents. This step is crucial for ensuring that the recycled oil meets or surpasses the required industrial standards.

6. Quality Testing and Certification

Before leaving the plant, the recycled oil must undergo thorough viscosity, flash point, and sulfur content, among other critical standards, testing. API, ISO, or ASTM standards show that the recycled base oil can be trusted, is safe to use, and can be sold in open markets.

7. Packaging and Distribution

At last, the recycled oil fills containers that have also been sealed for safe, secure transport or for distribution. With the right containers, the recycled oil can be safely transported and will be safeguarded against contamination. Thus, the product will have only undergone repaired; transport will finish the cycle of waste.

Equipment Used in Lube Oil Recycling

Used lube oil recycling plants utilize specially designed machinery to recover high-quality base oil from used oil. How one selects and designs these machines determines how well the process flows, the quality of the end-product, and how safe the entire process is to the environment.

The following is a list of equipment and systems used when processing used lube oil:

- Settling Tanks: Being the first stage of separation, these systems allow water, sludge, and heavy particles to settle to the bottom. Well-designed systems allow for the smoother processing of downstream systems.

- Vacuum Distillation Units: The heart of the recycling process, these systems remove oil from contaminants under low pressure while preventing oil from overheating.

- Clay Filtration Reactors: Used for chemical, these systems recover the color of the oil, remove residual acids, heavy metals, and any other impurities to enhance the stability and oil recovery for improved resale.

- Filtration Systems: These systems go through multiple stages to recover the oil and refine it to ensure it meets quality standards.

- Additive Blending Units (optional): Used for finished lubricants, these systems precisely blend the necessary performance additives for the oil based on specific industry standards.

Investing in quality, made-for-purpose lube oil recycling equipment guarantees reliable, consistent output, higher recovery rates, and improved compliance with the set environmental standards.

Benefits of Using a Professional Lube Oil Recycling Plant

Operating a professional lubricating oil recycling plant encompasses a lot more than just waste lube management.

First of all, it generates operational efficiency. Most modern recycling facilities are able to process large volumes of used oil, which guarantees consistent production of high-grade recycled base oil. Automation techniques, together with advanced monitoring systems, eliminate human errors, which helps reduce variability in processes, and enhances energy efficiency.

Another advantage is the production of recycled oil that meets the oil industry specifications. Through precise distillation, chemical treatment, and advanced filtration systems, professional oil recycling plants provide base oil that can be used in the blending of motor oils, industrial lubricants, and hydraulic fluids. The quality and consistent oil recycling increases the market credibility of businesses, providing the oil with more commercial opportunities.

Environmental and occupational safety risks are also enhanced with professional oil recycling plants. Containment systems, automated recycling processes, and high-level purification engineering provide considerable occupational and environmental hazard risk reduction while fulfilling stringent local and global environmental requirements.

Lastly, the operational efficiency of waste oil recycling facilities contributes to long-term, sustained profitability. By converting waste oil into a useful resource efficiently, businesses reduce dependency on virgin oil.

To Sum Up

Used lube oil recycling is not just about waste disposal; it is a strategic transformation of a liability into an asset. A professional lube oil recycling plant converts oil into high-value economic and environmental returns. Success relies on the economic value of the engineering quality of the equipment. Strategic investment in a powerful system guarantees quality and long-term system sustainability and profitability of lube oil recycling, allowing resource forecasting.

How about starting your lube oil recycling business? Please get in touch with YANGJIANG so that we can develop bespoke solutions for your needs.

Recommended Products