As a professional manufacturer of used oil distillation equipment, we are always asked the same question by customers worldwide: Can used motor oil be distilled to clean diesel fuel? The answer is affirmative. With the right technology, used motor oil can not only be distilled, but also be very profitable and environmentally friendly.

In this article, we will take you through the explanation of why used oil is distilled, the main technologies that can be employed, the way distillation is done, and the benefits to businesses and the environment.

Why Distill Used Motor Oil?

Used motor oil is arguably the most common industrial waste in the world, but it also contains valuable hydrocarbons that are recyclable. Should it be dumped or burned, not only does it pollute soil, water, and air, but it also wastes a potential energy source. And so, distillation used motor oil has become a widely used and environmentally-friendly method.

By means of a controlled Used oil distillation process, wasted lubricants are transformed into usable diesel fuel instead of being discarded as poisonous waste. This allows businesses to lower their fuel costs, create secondary income, and comply with strict environmental regulations. Distillation of used oil simultaneously decreases dependence on traditional petroleum refining, which also helps towards global quests for sustainability and the circular economy.

In transportation, power generation business, and heavy machinery operations, recycling waste oil to clean diesel means lower operating costs, guaranteed fuel supply, and a cleaner reputation in line with current environmental measures.

Types of Used Motor Oil Distillation

When recycling used motor oil into clean diesel, producers can pick from several proven technologies. The best method hinges on how much fuel you need, how clean you want the finished product, and how much money you can spend upfront. Here are the three methods you will usually see:

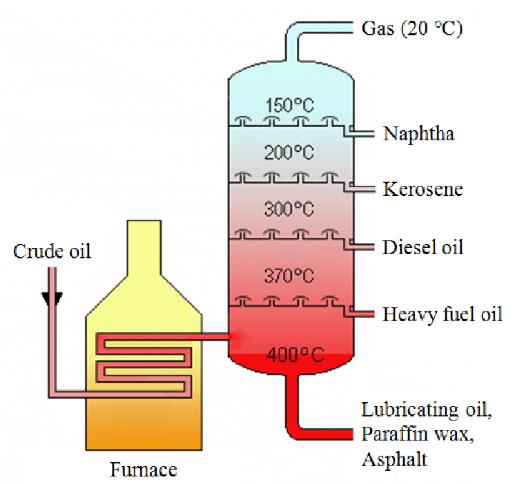

Type 1: Atmospheric Distillation

Atmospheric distillation is the oldest and simplest method for producing new fuel. First, the used oil is gently heated at normal air pressure. Lighter parts of the oil turn to vapor, travel up the column, and then condense back into diesel. The machines used are inexpensive and easy to run, making this an appealing choice for hobbyists and small shops. However, the finished diesel may still carry some harmful impurities and can sometimes smell bad. Because the oil is exposed to higher temperatures for longer, there is also a risk of the carbon chains breaking. For this reason, this method works best when buyers are not too strict about fuel grade.

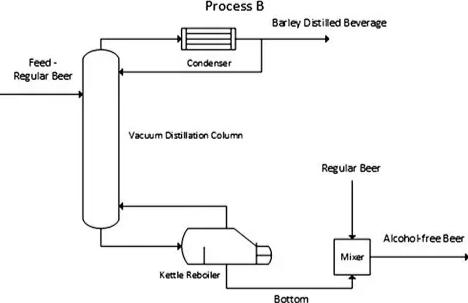

Type 2: Vacuum Distillation

Vacuum distillation has become the go-to technology for larger, continuously running plants. By cutting the pressure inside the column, the oil boils at lower temperatures. This prevents thermal cracking and keeps the heavier, unwanted compounds from breaking down into unwanted, possibly harmful byproducts. The resulting diesel has a brighter color, a much milder odor, and better stability. Although vacuum rigs cost more to buy and install, they use less fuel to run, have longer lifespans, and can easily keep up with the demands of commercial-grade recycling.

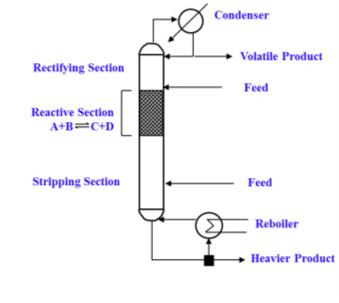

Type 3: Catalytic Distillation

Catalytic distillation combines two processes: separating lighter compounds and refining them using a catalyst. The catalyst assists in cracking larger hydrocarbon molecules and in removing harmful impurities like sulfur, nitrogen, and heavy metals. The final diesel product comes out with a quality very close to that required by commercial standards, making it suitable for a broader range of applications. This technique is ideal for companies aiming for high-grade diesel while achieving strict environmental regulations.

Many modern oil distillation facilities now use vacuum columns together with catalytic distillation. This hybrid approach ensures the best trade-off between low operating costs and high product quality.

Used Motor Oil Distillation Process

Refining used motor oil into clean diesel does not have to be complicated, but actually, the distillation of used oil itself is straightforward in concept: it distills valuable hydrocarbons out of useless garbage with carefully controlled heat and advanced refining processes. It is unlike simple burning or filtration in that it specifically focuses on making trash into a new, high-quality fuel product.

Step 1: Preparing the Oil

It starts with pre-treatment. Think of this step as “cleansing the raw material.” Water, dust, and heavy sludge are removed so that the oil entering the distillation unit is stable and ready to be refined. Proper preparation provides the equipment with a longer lifespan and smoother operation.

Step 2: Thermal Separation

Below is the heart of the process—the distillation reactor. The oil that has been pre-treated is warmed with care in such a way that different molecules of hydrocarbons are divided according to their boiling point. This process requires less energy when done under vacuum and with less cracking, yielding better-quality fractions of fuel.

Step 3: Capturing the Diesel

The vapors of the fractions are led to a condenser and then condensed back into liquid. Here, the clean diesel is beginning to be formed. The other fractions, such as base oil or bitumen, can be trapped too, yielding a number of value streams for the companies.

Step 4: Polishing the Product

In order to stabilize the recycled diesel into a clear and odourless form, it is subjected to polishing. Sulfur and other trace contaminants are removed by catalysts, clay filters, or decolorization units, giving a commercial quality finish to the fuel.

Step 5: Ready-to-Use Diesel

The result is clean diesel fuel that can be used in generators, heavy equipment, or blended with standard diesel fuel. Instead of an environmental loss, used motor oil is refurbished as a valuable energy option.

Our used oil distillation plants integrate these steps into a smooth-running system that’s energy efficient and capable of producing a consistent yield, encouraging businesses to turn waste into profitable gain in the long term.

Benefits of Distilling Used Motor Oil to Diesel

Choosing used oil distillation to process waste motor oil into diesel offers a wide range of economic, environmental, and business benefits for businesses. Instead of disposing of used oil as a hazardous byproduct, distillation allows businesses to unlock its latent value and gain a competitive advantage.

- Enormous Cost Savings: Fuel is one of the largest expenses for transportation, construction, and energy industries. With the implementation of distillation used motor oil technology, businesses are able to recycle their waste oil into usable diesel, avoiding the purchase of commercial fuels and saving operating costs by an enormous amount.

- Environmental Protection: Used oil can contaminate soil, rivers, and even drinking water if not handled carefully. Recycling waste oil prevents pollution and takes a potential hazard and turns it into a consumable form of energy. This helps businesses to abide by environmental laws while promoting a greener, cleaner, and more sustainable business image.

- High Recovery Rates and Energy Efficiency: New used oil distillation plants aim at high recovery efficiency, which produces maximum output per ton of used oil. This is economically and environmentally suitable.

- Business and Compliance Opportunities: In the majority of the world’s regions, governments encourage or require recycling of utilized lubricants. Businesses that invest in distillation equipment not only comply with such regulations but also open new opportunities by selling recycled diesel to the local markets.

Generally, refining used motor oil to diesel is a wise investment—transforming waste into profit, ensuring an inexhaustible source of fuel, and contributing to global efforts towards a circular economy and sustainable development.

Final

Used motor oil distillation to diesel is not just a technical process—a good business investment and a very significant step towards environmental sustainability. By using waste oil distillation equipment of the latest technology, used oil can be reconverted to useful fuel instead of contaminating the environment.

As a professional manufacturer, we supply properly designed and stable distillation plants according to your capacity and budget. If you are keen on waste-to-wealth conversion, kindly contact us today to learn more about our distillation used motor oil solutions.

Recommended Products