Environmental regulations are becoming stricter, and the recycled base oil market is growing, so waste oil recycling has turned into a great investment opportunity everywhere. Yet, one major decision will mainly determine the outcome of a waste oil recycling project – the right selection of the oil distillation plant.

Processing techniques vary according to the different types of waste oil. Mixing up the oil distillation technique may lead to oil loss, high power consumption, unsteady operation, and even exceeding the local environmental requirements. Therefore, knowing how to pick the most suitable oil distillation plant becomes imperative for securing the long-term profitability and uninterrupted operation.

This article shares the critical points you need to keep in mind while selecting an oil distillation plant for waste oil treatment, which will be based on practical project experience and industry best practices.

Understand Your Waste Oil and Recycling Goals First

It is paramount to specify the kind of waste oil and the outcomes of the recycling project before choosing the oil distillation plant. Practically, most of the operational problems are not due to the quality of equipment, but rather to the wrong distillation system being chosen for the specific type of raw material.

The understanding of your waste oil and recycling goals can contribute greatly to the long-term stability in operation, the quality of oil being produced, and the predictability of operating costs.

Sources of Waste Oil

Recycled waste oil projects can be traced back to several industrial and automotive sources. The following waste oils are the most frequently treated ones:

- Lubricating oil from engines in automobiles and machines that are no longer useful

- Waste oil from industrial plants, which is damaged or contaminated oil, along with mechanical parts

- Industry’s output of oil, which is completely useless due to processing and hence disposed of

- Power grid equipment gets oil, which is decommissioned or has reached maximum life, thus transformer oil recycling is carried out

- Oil that has been mixed and collected from different places

The composition, level of contamination, and chemical reactions during the heating process are different for each waste oil type. The factors mentioned must be taken into account while either making or choosing a suitable waste oil distillation unit.

How Waste Oil Characteristics Impact Selection of Equipment

The waste oil’s physical and chemical properties have a direct impact on the distillation plant design as well as the design of the whole system that supports it. Among the main factors that need to be analyzed are:

Water content: Large amounts of water necessitate dehydration; otherwise, the distillation process will be unstable.

- Solid contaminants: The presence of these affects the amount of pretreatment and filtration needed.

- Chemical additives: Some additives and detergents present in the used oil cannot tolerate high temperatures.

- Boiling range and viscosity: These parameters, along with temperature and pressure settings, determine distillation efficiency.

In large and professional waste oil recycling projects, the analysis of raw materials is usually done before the final selection of equipment. This method allows the distillation process to be set up correctly, which in turn minimizes the risk of failure and maximizes the energy recovery from oil right at the start.

Selection Factor 1: Distillation Technology

Distillation technology is the heart of a waste oil recycling plant. The right technology choice will influence oil yield, product quality, and safety during operation.

Major Distillation Technologies for Waste Oil

Waste oil recycling plants generally rely on the following distillation technologies:

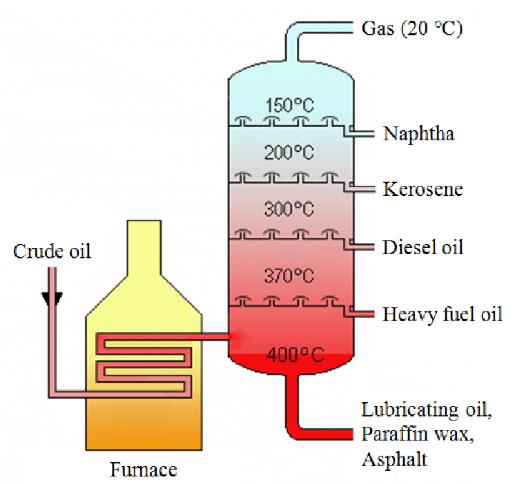

- Atmospheric distillation: with its straightforward design, but demanding high temperatures during operation.

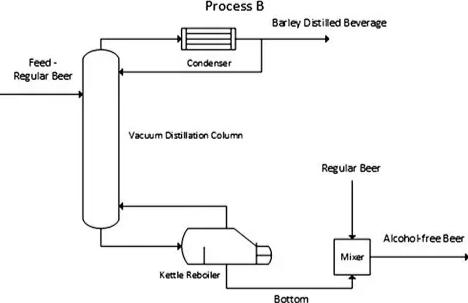

- Vacuum distillation: conducts its distillation under lower pressure to make the boiling points of the materials decrease.

- Molecular distillation: basically, the only way to obtain very rare, high-priced, and exceptional quality oils.

Vacuum distillation, of all these methods, is by far the most popular in oil recycling projects.

The main reasons why vacuum distillation of waste oils is the preferred option are as follows:

Firstly, vacuum distillation plants run at lower temperatures than atmospheric systems, and this change in the process gives a lot of good effects:

- Less of the oil is thermally cracked

- More base oil can be recovered

- The product color is better and more stable

- Carbonization and equipment fouling are less likely to occur

- Energy efficiency is improved in the long run

In the case of a vacuum oil distillation plant, the waste oil recycling project is mostly characterized by the best investment cost, operating safety, and output quality.

Selection Factor 2: Processing Capacity and Scalability

The correct choice of processing capacity is very important for the stable operation and acceptable return on investment. The capacity of the oil distillation plant should be determined based on the real volume of waste oil that is going to be available, the expected operating hours, and the long-term supply stability. An oversized system causes an increase in both capital and energy costs; on the other hand, an undersized plant will restrict production and thus lower profitability.

Scalability is a key factor, too. A waste oil distillation system with good design should not only allow for future capacity expansion but also the addition of other modules such as refining units or automation upgrades, thus enabling the project to grow without undergoing major restructuring.

Selection Factor 3: Environmental Protection and Compliance

Among other cities and countries, environmental compliance is a major issue in waste oil recycling projects for international markets.

- A dependable oil distillation plant must possess:

- Control systems for odors and emissions, together with exhaust gas treatment

- Methods for treating or recycling wastewater

- Proper handling and disposal of residues and sludge

The design of the equipment should adhere to the local environmental regulations and also support certification requirements like CE or equivalent standards. Environmentally friendly waste oil recycling plants not only mitigate regulatory risks but also enhance project sustainability.

Selection Factor 4: Automation Level and Operating Cost

Automation is a factor that significantly influences the stability and cost-effectiveness of the plant operation.

- Contemporary oil distillation systems usually contain:

- Control systems based on PLC

- Automatic regulation of temperature and pressure

- Alarm and safety interlock functions

The level of automation that has been brought to the highest point brings along the benefits of reduced labor costs, errors made by human beings, and improving the quality of the products consistently. Along with operating costs, energy consumption, maintenance frequency, spare parts availability, and system reliability must be taken into account and evaluated carefully.

How to Evaluate a Reliable Oil Distillation Plant Supplier

A reliable oil distillation plant supplier is not just about the equipment. The supplier must have proven waste oil recycling project experience, since practical knowledge can support the avoidance of design and operational problems. Not a standard system, but the supplier should be able to configure the system according to the different waste oil characteristics.

What is more, professional technical support such as installation, commissioning, and operator training assistance, has a very big impact on stability for long periods of time. Regular spare parts supply and prompt after-sales service are additional factors that guarantee the oil distillation plant functions smoothly.

Next Step

The selection of an oil distillation plant is not just about selecting the right equipment but is a strategic choice that will impact operating stability, product quality, and investment return for a long time. Every waste oil recycling project has its own set of needs, which are determined by the nature of the raw materials, the capacity of the processing plant, and the environmental regulations of the area.

So, if you are considering a waste oil recycling project or looking for an oil distillation solution, seeking professional technical advice may save you from making expensive mistakes during the initial stage. Reach out to us to talk about your type of waste oil, processing goals, and the conditions of the project. Our technical team will indeed provide a bespoke oil distillation solution that is specifically designed for your requirements!

Recommended Products