Every year, the world produces waste oil that is difficult to measure, which comes from automobile repair plants, large chemical enterprises, and other fields. If the waste oil can not be properly disposed of, discarded, or buried, it will cause immeasurable damage to the environment. So it is very important to deal with the waste oil properly. There are several ways to deal with waste oil. They use waste oil filter equipment to filter waste oil to obtain clean base oil or use waste oil recovery machines to recover waste oil to obtain base oil. These two methods are the most commonly used by many users.

It is estimated that at present, the waste oil produced by all kinds of construction machinery and equipment, automobiles, ships, airplanes and trains, and other large-scale machinery in our country is 25 million to 30 million tons per year. These waste lubricating oil can be recycled after proper process treatment to remove the deteriorated components and foreign impurities and pollutants. This method can be used in technology, environmental protection, rational utilization of resources, and From the economic point of view, it is a proper way to deal with it. However according to the statistics of relevant departments, the recycling rate of waste oil is only 20%, so where is the waste oil?

Waste Oil Treatment Method

Discard

Waste engine oil is always in the position of “waste” because of its low economic value. People often don’t pay much attention to the small amount of waste oil and pour it into the river, open field, or garbage can. This method will cause significant environmental pollution and waste resources. Research shows that a bucket (volume of 200L) of waste oil can pollute 3.5 square kilometers of water surface when poured into the water. What’s more serious is that the lubricating oil contains 3,4-benzophenone (PAH) and other polycyclic aromatic hydrocarbons (mainly existing in a mineral base oil), which have been proven to have a strong carcinogenic effect; the chlorinated polycyclic aromatic compounds, such as PCBs, are also substances with a strong toxic effect on human beings; the heavy metal salt additives contained in lubricating oil and extreme pressure antiwear with chlorine, sulfur, and phosphorus Organic substances, such as agents, are harmful to human beings and organisms. These substances mixed in water may eventually harm human health through various channels.

Incinerate

At present, using waste oil as fuel is also a common treatment method. Many construction sites will mix waste oil with other construction wastes that need to be incinerated and burn and destroy these buildings. This waste oil can produce good combustion-supporting effect, and this treatment method is also very harmful to the environment. Although the government has repeatedly stopped it, many illegal builders do it secretly to save money.

Recycling

In recent years, the technology of waste oil regeneration has spread to the people, and many refineries, large and small, have appeared in the market. They will go to the construction site to recycle the waste oil, and then transport it to the refinery to manufacture the waste oil. The poor quality waste oil will be distilled, cooled, bleached, and other “renovation” means to produce fuel oil, and then with the regular national standard oil. Blending at one-third or even one-half is the source of poor diesel. The waste oil with good quality is treated by proper process, and the deteriorated components and foreign impurities are removed to become regenerated lubricating oil, which then flows to the oil market through packaging. Although this method is always a reasonable way to deal with it in all aspects, most of the small vendors can not make precise control and strict requirements for the production process and method, and the quality of the oil products produced does not meet the standards, which is the reason why all kinds of fake brand oil are overflowing in the market.

Other

The waste oil is sprayed on the road easily to raise dust, and the dust is adhered to by its adhesion function, which plays a dust-proof role and is also a treatment method of waste lubricating oil. In the United States, a significant proportion of recycled used lubricants are used for this purpose. However, when it rains, the waste oil sprayed on the road will also be washed by the rainwater into the drainage ditch, and finally into the river to pollute the water quality, or into the soil to pollute the soil, so it will also pollute the environment.

First, let’s talk about the source of waste oil. Engine oil is widely used in machinery, chemical industry, and other fields. During the use of clean base oil, impurities such as dust, metal chips, water, or chemicals may mix with clean base oil. It has been used as lubricating oil, hydraulic fluid, heat transfer fluid, buoyancy fluid and other similar purpose oil mixed with impurities can be considered as waste oil.

How to recycle Waste Oil Mixed with Various Impurities?

Remove Water from the Waste Oil

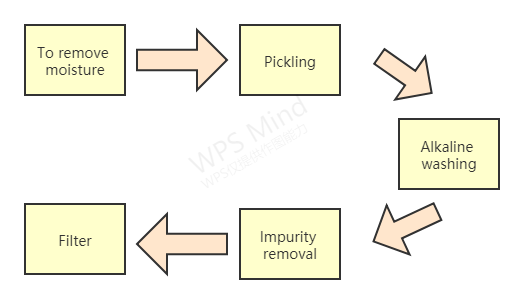

The first method is acid – clay process. This method is divided into several steps. The first step is to remove water from the waste oil. The waste oil recovery machine produced by Yangjiang can completely remove the water in the waste oil to obtain the dry waste oil for the next operation. The second step is to add sulfuric acid or hydrochloric acid to the pickling operation. The next step is to add the base and the preceding sulfuric or hydrochloric acid to get the neutral-treated oil. The fourth step is to add the activated clay to absorb the waste gas and impurities in the waste oil. Finally, the qualified oil can be obtained after filtration.

Distillation – Solvent Refining – Clay Process

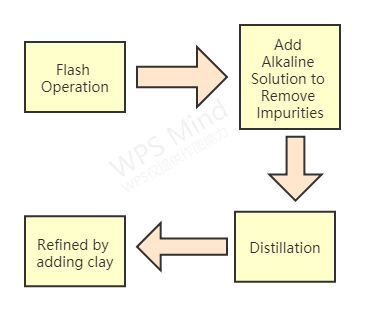

The second method is the distillation – solvent refining – clay process. The first step is to perform a flash operation to remove water from the oil to get dry oil. The next step is to add an alkaline solution to remove impurities in the waste oil to get a cleaner waste oil. Then distillation and ethanol or furfural extraction, and finally add clay refined waste oil, to get clean lubricating oil. This method is simpler than the previous one, and the result is a clean base oil.

The two methods are different, but both produce a clean base oil, and both have many advantages and few disadvantages. The above two methods of treating waste oil can be found in the products produced by Yangjiang, we can provide you with the best quality service.