Rising global lubricant standards demand cleaner, more stable, and environmentally compliant base oils. Group II base oils, characterized by their high saturate content, low sulfur levels, and excellent oxidation stability, are increasingly preferred in both automotive and industrial applications. However, achieving these performance characteristics is contingent primarily on how efficient the refining process is. Out of all the refining steps, solvent extraction is the most important in deciding a refinery’s ability to produce competitively priced, high-quality Group II base oils.

What Makes Group II Base Oils Different?

Understanding the importance of solvent extraction requires a look at what makes Group II base oils different. The American Petroleum Institute classifies base oils based on their saturate content, sulfur level, and viscosity index.

- Group I base oils are manufactured by simpler solvent refining processes. They have a higher percentage of impurities such as sulfur and aromatics, leading to lower oxidative stability, along with a darker color.

- Group II base oils are characterized by high-saturate levels (>90%) and very low sulfur content (<0.03%). This means a more colorless, clearer oil that provides greater high-temperature stability, less sludge build-up, and increased oxidation resistance.

The journey from a crude oil fraction to a pristine Group II base oil hinges on one critical step: the effective removal of these undesirable aromatic compounds, sulfur, and nitrogen. This is where solvent extraction proves indispensable.

The Role of Solvent Extraction in Achieving Group II Purity

Crude oil is a complex mixture of desirable molecules, mainly paraffins and naphthenes, with less desirable aromatic, sulfur, and nitrogen compounds. It is these impurities that make the oil unstable, dark in color, and prone to sludging.

That’s where the process of solvent extraction comes in. The process is one of physical separation that acts with great precision. There is the introduction of a special solvent into the feedstock, normally NMP or Furfural. This solvent exhibits a high affinity for unwanted aromatic compounds and impurities without mixing with the desirable saturated hydrocarbons.

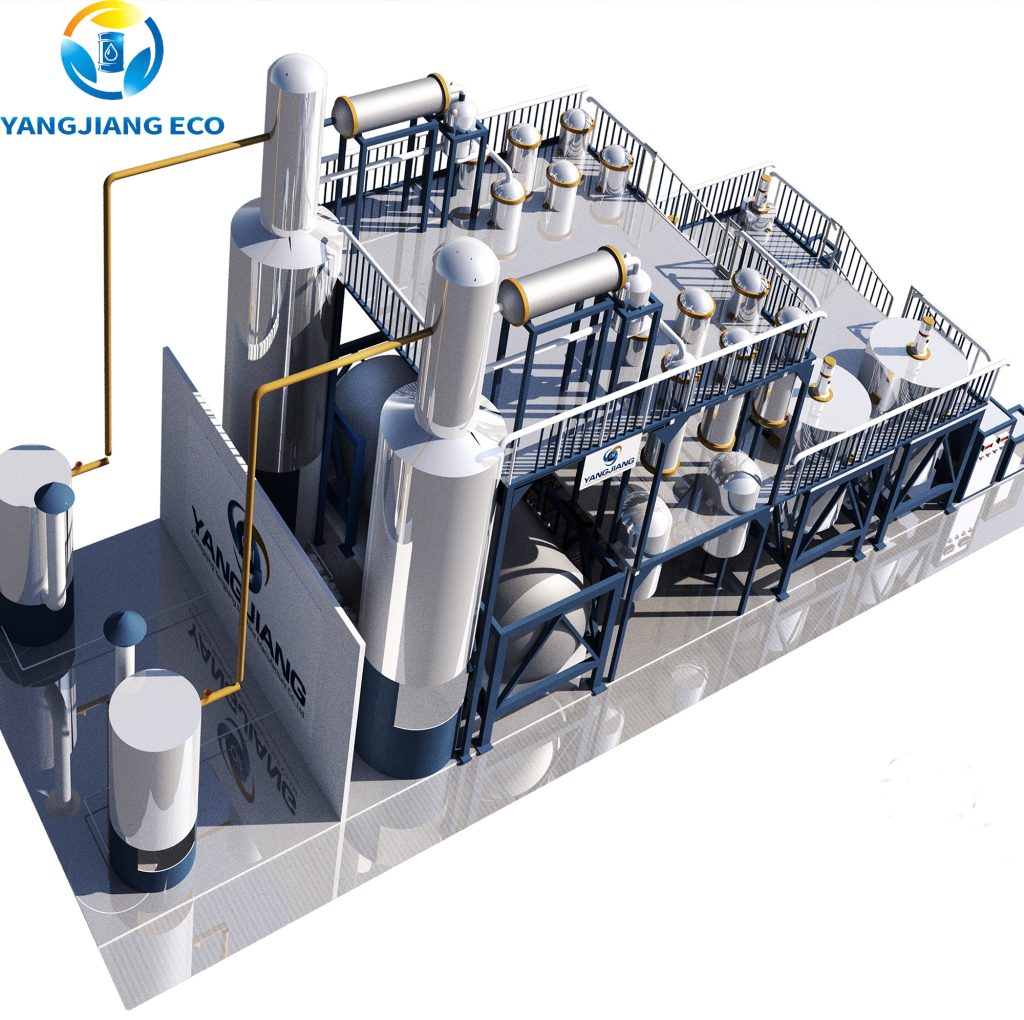

This contact, in our solvent extraction machines, takes place under highly controlled conditions, usually in an extraction column. The impurities dissolve into the solvent phase and are taken out with it, leaving behind a purified raffinate-the basis for high-quality Group II base oils. Without effective solvent extraction, true Group II base oils could not be produced.

Key Benefits of Using Advanced Solvent Extraction Technology

Investment in a modern solvent extraction plant represents a true value-creation decision, going well beyond simple specification compliance to real return on investment.

1. Purity and Product Integrity

The core function of any extraction system is one of purification. Advanced solvent extraction technology excels at this in the form of precise removal of unstable aromatic compounds, sulfur, and nitrogen, which leads to a base oil with outstanding color clarity and, more importantly, superior oxidation stability. This, for blenders, would mean that the final lubricant can support higher operating temperatures for longer periods, thus directly extending drain intervals and enhancing engine protection.

2. Higher Yield-Improved Process Economics

The older or less efficient the unit, the greater the possibility of significant yield loss, whereby desirable oil is unnecessarily removed with the extract stream. Modern solvent extraction equipment features optimized column internals combined with precise process controls to optimize the selectivity of the solvent. Such selectivity assures a sharper separation, consequently providing a higher recovery of valuable base oil from the same volume of feedstock and enhancing your overall base oil production profitability.

3. Operational Reliability and Reduced Energy Intensity

Downtime is expensive. Modern solvent extraction machines are designed to operate robustly and continually. Key enhancements include extremely efficient solvent recovery systems that minimize energy use per barrel of production and designs that prevent fouling. This means more predictable production, lower utility costs, and less unplanned maintenance, keeping your base oil plant running at maximum efficiency.

Solvent Extraction vs. Other Refining Methods

Different grades of base oil are manufactured by employing different refining steps; not all the methods have the same efficiency and cost-effectiveness. Among the different pre-treatment options, solvent extraction remains the most critical because it removes aromatics, sulfur, and nitrogen selectively before downstream hydroprocessing. While hydro-treating and hydrocracking are essential for their further upgrading, relying solely on these techniques increases energy consumption and reduces catalyst life, increasing operating costs.

The key differences between solvent extraction and other common refining methods can be outlined in the table below:

| Refining Method | Primary Purpose | Advantages | Limitations |

| Solvent Extraction | Remove aromatics, sulfur, and nitrogen from base oil feedstock | High yield of clean, stable base oil; reduces load on hydroprocessing; cost-effective | Cannot remove all impurities alone; requires precise process control |

| Hydro-Treating (HDT) | Saturates hydrocarbons and reduces sulfur | Improves stability; essential for final product specification | High hydrogen consumption if feedstock is aromatic-rich; less efficient without prior extraction |

| Hydrocracking | Deep refining for premium base oils | Produces very high-quality products; increases viscosity index | Expensive to operate; excessive hydrogen use; over-processing reduces overall yield |

The table below illustrates that solvent extraction is the most effective and economic first step in Group II production for making sure hydro-treating and hydrocracking units run efficiently, protect catalysts, lower energy consumption, and provide consistent, high-quality base oils. Without this step, achieving Group II specifications is more difficult and expensive.

How to Choose the Right Solvent Extraction Equipment Supplier

Obviously, the choice of a manufacturer for base oil solvent extraction systems is a central one in terms of product quality, operational effectiveness, and long-term profitability.

- First, consider engineering experience and technical capability. A reputable supplier should have satisfactory past experience in designing, manufacturing, and commissioning solvent extraction units for various types of crude and refineries of various scales. It has to demonstrate very strong process optimization skills in order to maximize yield and product quality.

- Second, assess technology and equipment design. Advanced systems should have optimized tower internals, efficient solvent recovery units, and be capable of flexible configurations to handle different feedstocks. Automation and control systems, such as integration with PLC or DCS, ensure stable operation while minimizing human error.

- Third, the modern techniques should be energy-efficient and environmentally compliant. Modern equipment should minimize energy consumption, reduce solvent losses, and adhere to more stringent environmental regulations for safety and sustainable operations.

- Finally, evaluate the after-sales support and service. A good supplier will offer a full range of services, including installation, training for operators, maintenance, and availability of spare parts. Long-term technical support maintains production quality consistently and ensures downtime is minimized.

By choosing a supplier with strong engineering expertise, advanced technology, energy-efficient design, and robust support, you are assured of a cost-effective and reliable solvent extraction solution that will guarantee high-quality Group II base oil production.

To Conclude

The high quality of Group II base oils largely depends on efficient solvent extraction. Solvent extraction removes aromatics, sulfur, and nitrogen early in the refining chain, which improves product stability, yield and reduces costs for downstream processing. Advanced technology in extraction and a reliable solvent extraction equipment supplier are key to consistent performance, energy efficiency, and compliance with regulations.

For refiners and lubricant manufacturers who need to keep pace with today’s market demands, finding the right solution in solvent extraction isn’t optional but is an investment in delivering premium base oils in tandem with optimized operational efficiency and long-term profitability.

Seeking professional support? Contact YANGJIANG today to discuss how our solvent extraction systems can meet your refinery’s particular needs!

Recommended Products