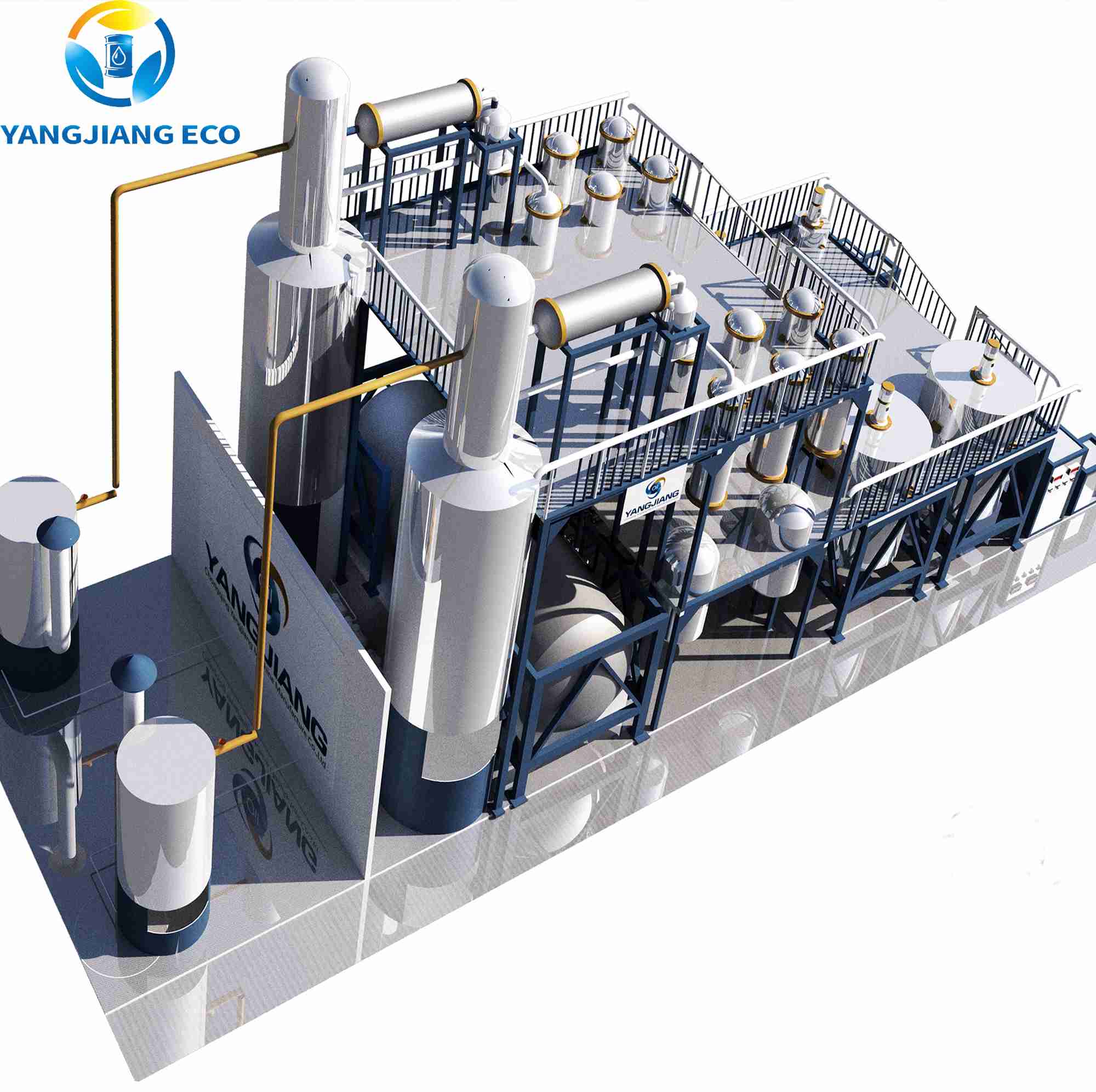

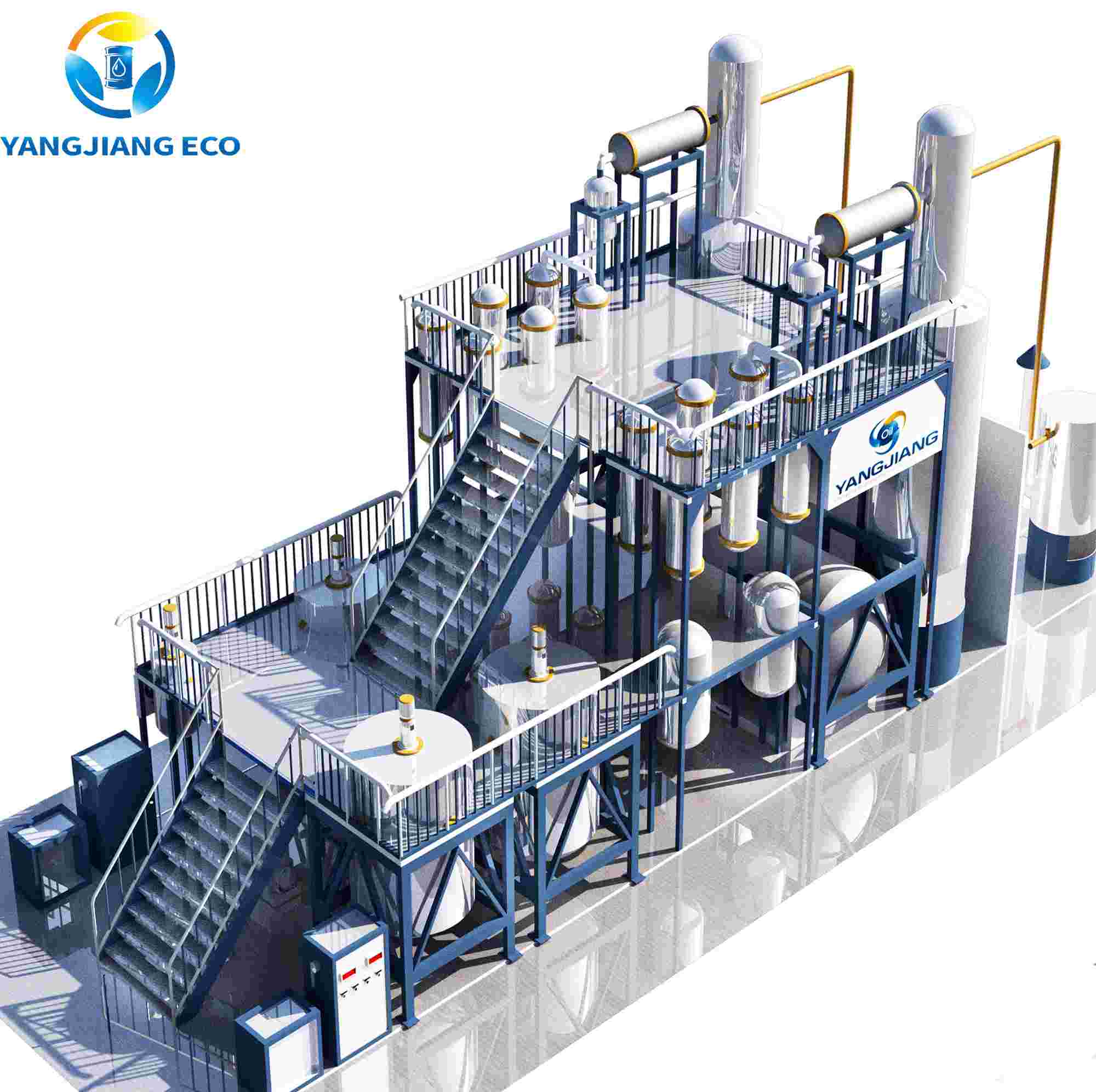

YJ-SR Base oil Solvent Extraction Machine

Deeply purify and refine all distilled oil, improve the oil standard close to API Group II

YJ-SR base oil solvent extraction machine can refine all kinds of recycled base oil, vacuum side streams,acid-refined oil, black diesel oil, waste hydraulic oil, waste transformer oil, and all kinds of waste mineral oil that don’t contain solid particles into new oil. Through solvent refining, impurities in lubricating oil can be effectively removed, the purity and quality of base oil can be improved, close to the standard requirements of API Group II base oil classification, increasing the viscosity index of base oil, reducing sulfur content, increasing saturation, and removing impurities.

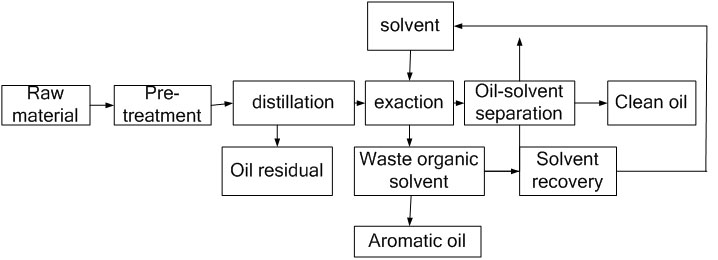

Technology Description of YJ-SR Base oil Solvent Extraction Machine

We adopt a composite solvent in conjunction with separation, extraction, and displacement device to displace and dissolve sulfides, oxides, nitrides, resins, asphalt, aromatics, and unsaturated hydrocarbons in the base oil. Finally, the used solvent can be recycled and reused, and the refining process is completely pollution-free. The processing process does not produce secondary waste, no need to add white clay and silica gel or other chemical additives, with low refining cost and low loss. It could get more than 98% refined oil, and the solvent loss is only 0.8%-2%.

Working Process

- Extraction and Centrifugal Separation: Base oil after distillation will react with solvent in five-stage centrifugal extractors, sulfides, oxides, nitrides, colloid, asphalt, arene, and unsaturated hydrocarbon in the base oil are completely dissolved in the solvent. The solvent oil with a different specific gravity will be separated from the base oil through the centrifuge.

- Recovery of Solvent: After the extraction and centrifugal separation process, the used solvent will be recovered by a stainless steel solvent distillation kettle for reuse again and again.

- Separation of Solvent from Base oil: After 5-stage centrifugal extractors, the semi-finished oil still contains about 5% solvent, which will go to a semi-finished oil distillation kettle for heating to 150- 160 degrees to distill all solvent out.

- Heater & Heat Exchange: Can choose electromagnetic heating, fuel oil heating, natural gas heating, thermal oil heating.

- Exhaust Gas Treatment: With our exhaust gas treatment, the exhaust gas will be burned to oxidize and decompose the VOC compositions in the exhaust gas, so as to meet the requirements of “Overall Air Pollutants Emission Standards”.

Application Field of YJ-SR Base oil Solvent Extraction Machine

Centrifugal extractors, also known as Liquid-liquid centrifugal extractors or centrifugal contactors, have been widely used in industries such as the pharmaceutical, fine chemical, food products, nuclear etc.

- Oil industry: Lubricating oil extraction, diesel desulfurization, and so on.

- Pharmaceutical industry: Such as used for extracting ethyl acetate, methylene dichloride, normal butanol, chloroform, or extracting the Chinese traditional medicine.

- Food industry: Extraction and separation of lactic acid and citric acid fermentation broth, edible oil, food pigment, etc.

- Environmental protection industry: Used single-stage or multistage extraction and reverse extraction to treat wastewater with phenol or acid, printing and dyeing wastewater (H acid, T acid, etc.), DMF wastewater, naphthalene sulfonic acid wastewater, etc.

In addition, oil-water separation or extraction for marine sewage, groundwater, or separating organic solvents from the water.

YANGJIANG is committed to new product research and development, dedicated to providing you with the highest cost-effective, high-quality products and meticulous after-sales service. If you have any requirements and questions about the Single-stage and Multi-stage Centrifugal Extractor, please feel free to contact us.